FIGURE 20

UT Electronic Controls 1012-925A

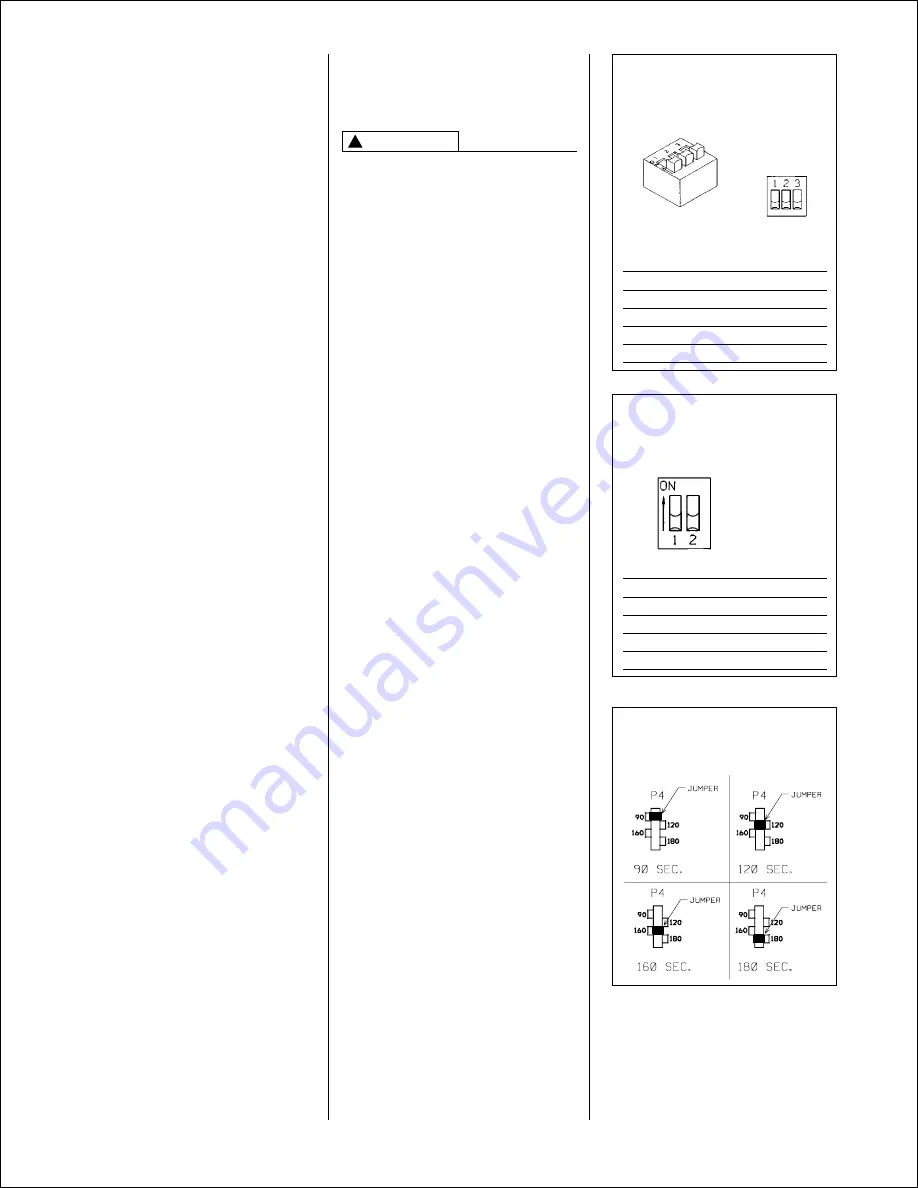

BLOWER OFF TIMINGS

5. After 5 seconds of inter-purge, the

the inducer operate for 180 seconds

before the next ignition trial.

6. It repeats this process up to four times.

At the end of the last try, the inducer

stops immediately.

7. The above sequence will repeat after a

goes through another set of trials for

ignition.

1. FAN SPEED — motor runs on this

speed when the thermostat is in the

“FAN” position.

2. COOL — connect desired cooling

3. HEAT — connect desired heating

4. HEAT/COOL — connect desired

speed when heating and cooling

speed are the same.

This tap not available on (-)GPJ

motor speeds to “HEAT” or “COOL” if

you use the “HEAT/COOL” terminal.

5. If heating and continuous speed are

the same, jump across “FAN” and

“HEAT” terminals.

This does not apply to (-)GPJ or

(-)GLJ models because the heat tap

functions as the continuous fan tap as

well.

See Figures 19, 20 & 21 for instructions

for setting the blower “OFF” timings.

GAS FURNACE (DIRECT

DRIVE) INSTRUCTIONS FOR

CHANGING BLOWER SPEED

The blower motor is wired for blower

speeds required for normal operation

as shown.

temperature rise after changing the

heating speed for any reason.

FIGURE 19

UT Electronic Controls 1028-928

BLOWER OFF TIMINGS

Содержание GLH series

Страница 23: ...23 FIGURE 18 UTEC 1028 928 CONTROL BOARD TWINNING CONNECTION TWO STAGE OPERATION a099301...

Страница 27: ...27 BLOWER PERFORMANCE DATA GPH UPFLOW HORIZONTAL MODELS BLOWER PERFORMANCE DATA GLH DOWNFLOW MODELS...

Страница 28: ...28 BLOWER PERFORMANCE DATA GLJ DOWNFLOW MODELS ONLY BLOWER PERFORMANCE DATA GPJ UPFLOW HORIZONTAL MODELS...

Страница 33: ...33 FIGURE 29 TROUBLESHOOTING FLOWCHART continued on next page PREPURGE...

Страница 34: ...34 FIGURE 29 TROUBLESHOOTING FLOWCHART CONTINUED 92 22744 19 01...