Section

III

Drive Reassembly

Refer to Parts Drawing Figure 19.

1.

GENERAL

a. Clean all parts to be reassembled and coat all tapered

roller bearing cups and pinion teeth with an SAE 20 (or

heavier) oil. DO NOT lubricate gear teeth prior to

assembly on shaft.

b. Heat all ball bearings and tapered roller bearing cones

in an oven to 275°F(135°C).

CAUTION:

Do not apply flame directly to bearings or

rest bearings directly on a heated surface.

c. Slide or press all ball bearings and bearing cones tight

against the shoulder.

CAUTION:

Do not apply force to the bearing rollers or

roller cage. Apply force against the inner race only.

2.

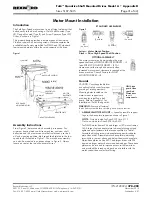

ASSEMBLY OF TAPERED ROLLER BEARING CUPS

a.

SIZE 5107 THRU 5315

— Drive high speed bearing

cup, Ref. #1A2 or 3A2, intermediate speed bearing

cup Ref. 2A2, and low speed bearing cup 4A2

squarely into their respective bearing bores of output

housing Ref. #11, with a press or steel bar as shown

in Figure 20.

3.

HIGH SPEED SHAFT ASSEMBLY —

Ref. #1A or 3A

Assembly.

Seat heated bearings cones, Ref. #1A1, 1A2 or 3A1 &

3A2, firmly against shaft shoulder or retaining ring.

CAUTION:

Allow bearings to cool. Apply a coat of oil to

the cooled bearings to lubricate and avoid scoring of

working surfaces.

Rexnord Industries, LLC 3001 W. Canal St., Milwaukee, WI 53208-4200 USA

378-200

(PN-2128394)

Telephone: 414-342-3131 Fax: 414-937-4359

November 2010

e-mail: [email protected] web: www.rexnord.com

Supersedes 6-07

Owners Manual

•

Falk™ Quadrive Shaft Mounted Drives Model A

(Page 18 of 44)

Sizes 5107-5315

Figure 20

RETAINING

RING 5107

THRU 5215

J25 ONLY

PINION

1A2 BEARING

1A1 BEARING

SHAFT

EXTENSION

Figure 21