Motor Mount Installation

2.

ATTACH MOTOR MOUNT TO DRIVE —

To determine the

number of housing flange fasteners to be removed for a given

shaft center and drive size, refer to Table 2. Remove and

discard appropriate number of housing flange fasteners, and

replace them with the longer support leg fasteners provided.

Attach support legs to the input side of drive with the hex nuts

on output side of drive. Tighten support leg and base plate

support fasteners to torque values specified in Table 1.

3.

MOUNT MOTOR —

Position motor on motor base

plate so that all mounting holes are in alignment. Install

and tighten motor fasteners.

4.

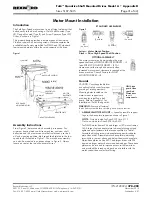

SPROCKET, PULLEY OR SHEAVE CONNECTION —

Mount power take-offs as close to drive and motor housing

as possible to avoid undue bearing load and shaft

deflection. Align the high speed shaft of drive square and

parallel with motor shaft by placing a straightedge across

the face of the sprockets or sheaves as illustrated in Figure

4. Check horizontal shaft alignment by placing one leg of

a square against the face of the sheave or sprocket with

the spirit level on the horizontal leg of the square.

Adjustment of the belt or chain is accomplished by turning

adjusting screws evenly. DO NOT over tighten belts or

chains. Over tightening belts or chains reduces belt/chain

and bearing life. When the required tension is reached,

tighten adjusting screw jam nuts to torques listed in Table 1.

Adjust chain tension to manufacturer’s specifications. Adjust

belts as follows:

The ideal belt tension is the lowest tension at which the belt

will not slip under peak load conditions. Check belt tension

frequently during the first 24 to 48 hours of run-in operation.

Keep belts free from foreign material which may cause

slippage. Inspect the V-belt drive periodically; re-tighten belts

if they are slipping.

Rexnord Industries, LLC 3001 W. Canal St., Milwaukee, WI 53208-4200 USA

378-200

(PN-2128394)

Telephone: 414-342-3131 Fax: 414-937-4359

November 2010

e-mail: [email protected] web: www.rexnord.com

Supersedes 6-07

S

SHORT

CENTERS

M

M EDIUM

CENTERS

L

LONG

CENTERS

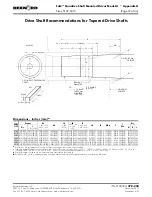

TABLE 2 — Support Leg Fastener Quantity

(Each Side)

Shaft

Centers

DRIVE SIZE

5107

5115

5203

5207

5215

5307

5315

Short

NA

NA

4

4

4

6

Medium

3

3

3

3

3

5

Long

2

2

2

2

2

4

Figure 3

RIGHT

WRONG

GEAR DRIVE WALL

LEVEL

SQUARE AND

PARALLEL

Figure 4

TABLE 1 — Motor Mount Fasteners & Torques

H

lb-ft (Nm)

DRIVE

SIZE

Support Leg to

Baseplate Support

Support Leg

to Housing

Adapter Plate to

Baseplate Support

Adjusting Screws

(W/O Adapter)

Adjusting Screws

(With Adapter)

Fastener Size

Tightening

Torque

Fastener Size

Tightening

Torque

Fastener Size

Tightening

Torque

Fastener Size

Tightening

Torque

Fastener Size

Tightening

Torque

5107

.375-16UNC x 1.00

28 (38)

.312-18UNC x 1.50

20 (26)

. . .

. . .

.625-11UNC x 5.00

60 (81)

. . .

. . .

5115

.375-16UNC x 1.00

28 (38)

.312-18UNC x 1.50

20 (26)

.625-11UNC x 1.00

60 (81)

.625-11UNC x 5.00

60 (81)

.750-10UNC x 6.00

108 (146)_

5203

.500-13UNC x 1.25

69 (94)

.375-16UNC x 2.00

28 (38)

.625-11UNC x 1.00

60 (81)

.625-11UNC x 5.00

60 (81)

1.000-8UNC x 6.00

180 (244)

5207

.500-13UNC x 1.25

69 (94)

.500-13UNC x 2.25

69 (94)

.625-11UNC x 1.00

60 (81)

.625-11UNC x 5.00

60 (81)

1.250-7UNC x 7.00

362 (491)

5215

.625-11UNC x 1.50 137 (186)

.500-13UNC x 2.25

69 (94)

.625-11UNC x 1.00

60 (81)

.625-11UNC x 5.00

60 (81)

1.250-7UNC x 7.00

362 (491)

5307

.750-10UNC x 1.75 245 (332)

.500-13UNC x 2.50

69 (94)

.625-11UNC x 1.00

60 (81)

.625-11UNC x 5.00

60 (81)

1.250-7UNC x 7.00

362 (491)

5315

.750-10UNC x 1.75 245 (332)

.500-13UNC x 2.50

69 (94)

.625-11UNC x 1.00

60 (81)

.625-11UNC x 5.00

60 (81)

1.250-7UNC x 7.00

362 (491)

H

All fasteners are Grade 5.

Appendix D

•

Falk™ Quadrive Shaft Mounted Drives Model A

(Page 32 of 44)

Sizes 5107-5315