2.0 Background to feed engineering

The use of mechanical vibrators for feeding material, dosing, screening or mixing of goods is long estab-

lished. Drives, with so called out-of-balance motors and vibrating equipment with electromagnetic drives are

certainly the most widely applied. Electromagnetic drives are more frequently used in automation engineer-

ing and hence some fundamental differences require further explanation. In general one is referring here to

vibratory feeders.

Vibratory feeders comprise the actual drive unit, including one or more coils, a reaction base, a spring sys-

tem and tooling, which can be in the form of a tray, tube, track or a bowl with a spiral track inside. Tray

shaped vibratory feeders that deflect in one direction, are used to convey material and are generally referred

to as “Linear Feeders“. Vibratory feeders with a spiral track and a spring/coil combination that gives a com-

posite motion that are used for sorting, orientating and feeding parts, are known as “Bowl Feeders“.

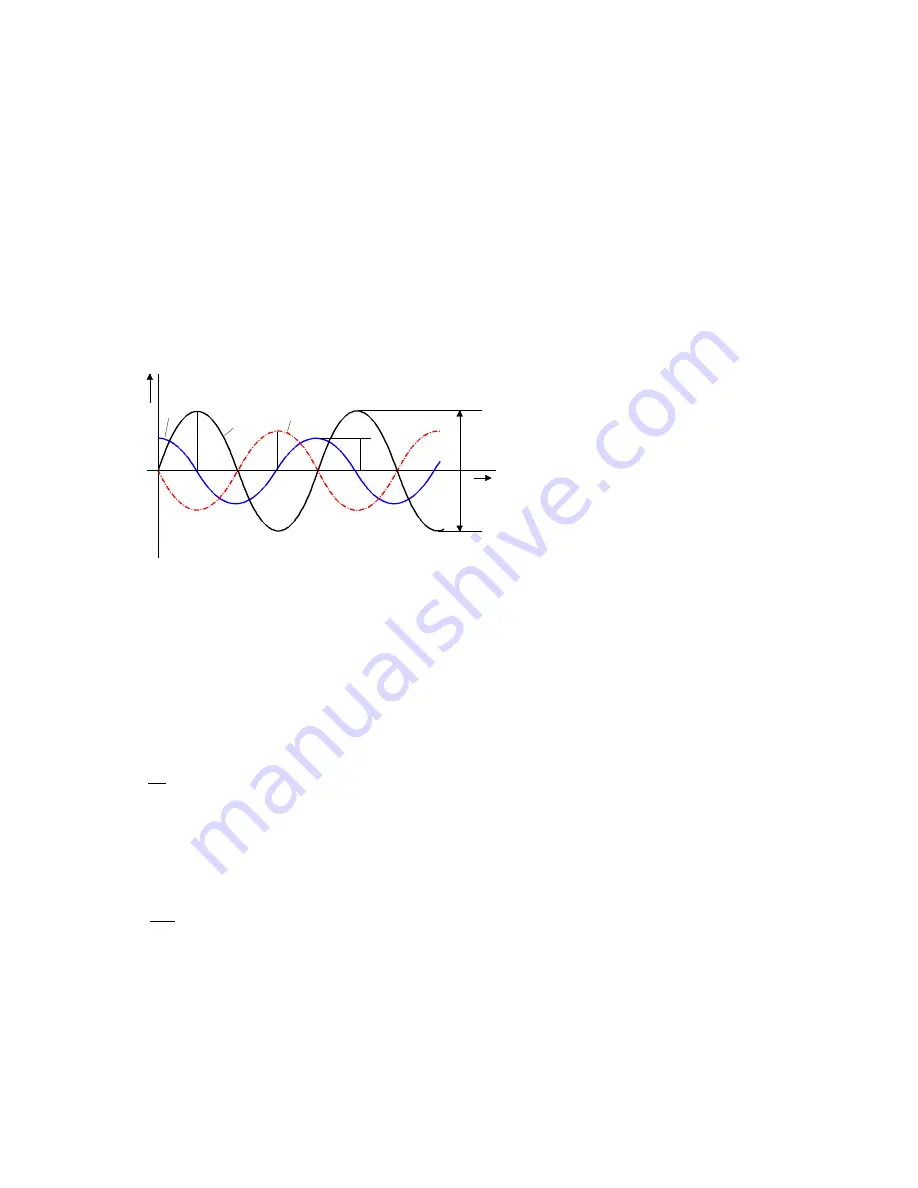

2.1 The vibration wave form

The vibratory motion in the case of a vibratory feeder moves backwards and forwards in a straight line. The

direction of movement is at a specific angle relative to horizontal, referred to as the “vibrating angle“. The

movement plotted against a time axis gives a curve approaching the shape of a sine wave.

s

Deflection

a

Acceleration

v

Speed

Diagram 1 The vibration curve

The sinusoidal waveform is derived from the formula

[mm]

where “s“ is the time based vibration movement, s

0

the amplitude (half of the total deflection) and

ω

the cycle

frequency (2

π

f ).

The vibrating speed is derived from the differential of deflection over time

with

the acceleration

with

2

t

s

s

ω

sin

0

=

t

s

dt

ds

v

ω

ω

cos

0

=

=

ω

0

0

s

v

=

t

s

dt

ds

a

ω

ω

sin

2

0

2

2

−

=

=

2

0

0

ω

s

a

=

S

a

v

S,a,v

Sn

t

a

0

s

0

v

0