5 Maintenance

5-8

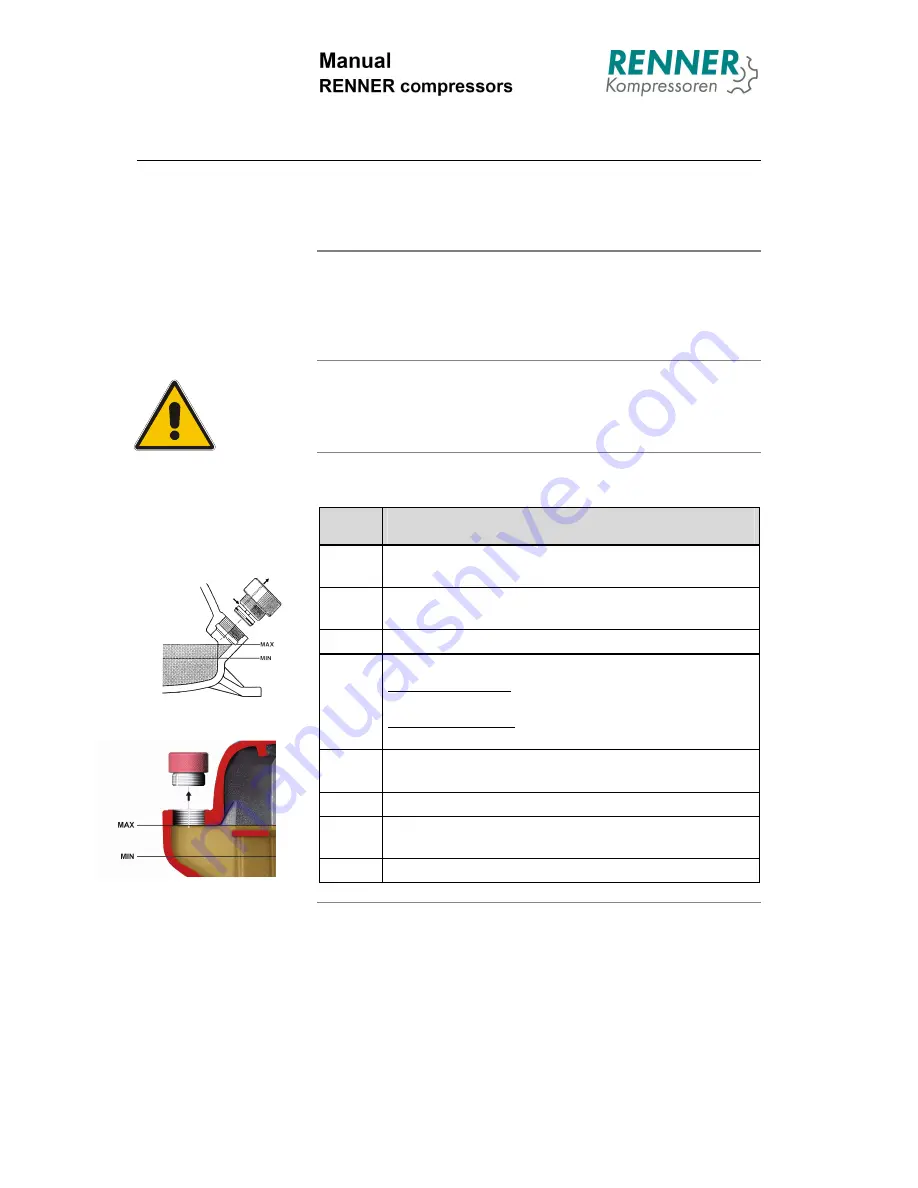

5.5 Checking oil level

This section outlines the procedure for checking the oil level in

the compressor.

The level in the oil tank is a key factor in the operational safety

of the unit. Due diligence should be exercised in conducting the

following checks at the specified times. Otherwise we cannot

accept liability in the event of damage.

Follow the safety instructions for venting the unit (see

Chap. 5.3)

Step

Instructions

1

Switch off the unit and take measures to prevent it

from being restarted.

2

Wait until the unit has been switched off for at least

three minutes.

3

Unscrew cap on filler neck of block by hand.

4

To check the oil level, look on the oil sight glasses:

Minimum oil level: Oil must not fall below half of the

oil sight glass

right next to

the thermal valve

Maximum oil level: Oil should not be higher than half

of the oil sight glass

over

the thermal valve

5

If necessary, refill to the maximum mark with oil of

the same kind.

6

Replace the oil filler plug firmly by hand.

7

Switch on the unit and check for leaks at the oil filler

neck.

8

If necessary, change the O-ring at the filler neck.

Content

General points

Checking the oil

level