39

1.800.627.4499

Integral Indirect Gas-Fired Heat Module

OPTION

6.6 UNIT START-UP ADJUSTMENTS

6.6.1 Burner Flames

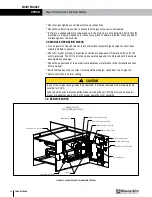

Prior to completing the start-up, check the appearance of the main burner flame. See images

below for characteristics of properly adjusted Natural Gas systems.

The burner flame should be predominantly blue in color and well defined and centered at the

tube entry. Distorted flame or yellow tipping of natural gas flame, or a long yellow flame on

propane, may be caused by lint and dirt accumulations inside burner or at burner ports, at

air inlet between burner and manifold pipe, or debris in the main burner orifice. Soft brush or

vacuum clean affected areas.

Poorly defined, substantially yellow flames, or flames that appear lazy, indicate poor air supply

to burners or excessive burner input. Verify gas supply type and manifold pressure with rating

plate information.

Poor air supply can be caused by obstructions or blockage in heat exchanger tubes or vent

discharge pipe. Inspect and clean as necessary to eliminate blockage. Vacuum any loose dirt or

loose debris. Clean heat exchanger tubes with a stiff brush. Poor flame characteristics can also

be caused by undersized combustion air openings or flue gas recirculation into combustion air

supply. Increase air opening size or re-direct flue products to prevent recirculation.

Reduced air delivery can also be the result of fan blade slippage, dirt accumulation on the fan

blade or low voltage to draft inducer motor. Inspect draft fan assembly and be sure the fan

blade is secure to motor shaft. Check the line voltage to the module.

The high-fire settings on the gas valve(s) have been factory-set using the maximum manifold

gas pressure as shown on the data label.

IMPORTANT

FIGURE 6.6.0 BURNER FLAME AT 1.2 INWC [298 PA]

MANIFOLD PRESSURE (DRAFT INDUCER AT HIGH SPEED)

FIGURE 6.6.1 BURNER FLAME AT HIGH FIRE 3.5 INWC [871 PA]

MANIFOLD PRESSURE (DRAFT INDUCER AT HIGH SPEED)

OPERATION