17

1.800.627.4499

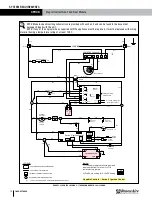

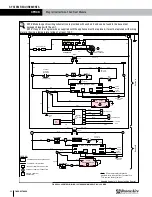

Integral Indirect Gas-Fired Heat Module

OPTION

FIGURE 2.3.1 CONTROL WIRING, 5:1 TURNDOWN MODULE, 50–150 MBH

SIZE

DATE

Description

REV

DRAWN

TCS

A

6/30/15

“ MA “ Control Wiring –

SC40 w/ 2 Spd. ID Fan - 115V

0

REVISED

SCALE

1 : 1

WS-MA-CC5-2S-2SV-115V

SHEET

1 of 1

50 Heatco Ct.

Cartersville Ga. 30120

770-529-2000

BLU

WHT (Com)

YEL

5

L1

L2

GRY

BLU

24V

BLK

AIR SWITCH -HI

GRY

BLU

YEL

APS-2

GRY

BLK

WHT

BLU

BLU

4

115 VAC

Hot

Neut

40 VA

XFMR 1

Capable Controls

–

Series 5 Ignition Control

BLU

YEL

24VAC Alarm

Indicator

YEL

Gnd

(V2)

Gnd

Syst.

Alarm

YEL

COM

2 STG GAS VALVE

LO

HI

WHT

FLAME

SENSOR

ROR

IGNITER

SPARK

Series 5 Ignition Control

Spark

MV

24V

APS

(PSW)

T-Stat

Sense

3

PUR

HI LIMIT

PUR

APS-1

AIR SWITCH -LO

ORG

ORG

ORG

ORG

ROLL OUT

SWITCH

ROLL OUT

SWITCH (2)

Maxitrol

SC40

T1

T2

T3

T4

T5

T6

T7

T8

COM

T9

HAPS

EST

R1

24V

E Valve

(+)

(-)

T10

T11

(-)

(+)

T1

T2

T' STAT

Factory

Jumper

Customer

Interlocks

(See Note)

EX

A

Va

lv

e

(+)

(-)

(+)

(-)

24V SIG

YEL

BLU

BLU

YEL

0

–

10 VDC Analag Iput

(Polarity Sensitive)

YEL

YEL

BLU

RED

BLK

GRY

BLU

YEL

IGNITION CONTROL

L1

IND

BLK

BLK

HI

DRAFT INDUCER

RED

LO

BLK

WHT

4

2

Br/W

CR1

1

3

YEL

Br/W

J1

Shunted

See Notes for Dip

Switch Setting

(2)

2

nd

ROLLOUT SWITCH ON HORIZONTAL BURNER TRAY ONLY

CUSTOMER PROVIDED COMPONENT

CUSTOMER / FIELD WIRING

INTERNAL TERMINAL CONNECTION

1

EXTERNAL TERMINAL CONNECTION

3

LEGEND:

BLU

BLU

CR1

1 2 3 4

ON

Notes:

1.) If Customer safety interlocks provided,

wire in series from Terminal 3 to T1&

remove factory jumper

2.) Dip Switch setting for 0-10VDC Analog

Models H(M,D)D125-175 and H(M,D)G125-200

2.3.2 Electrical Schematics

Valve can vary

SYSTEM REQUIREMENTS

NOTE: Module-specific wiring schematics are provided with each unit and can be found in the document

package shipped with the unit.

NOTE: If any of the original wire as supplied with the appliance must be replaced, it must be replaced with wiring

material having a temperature rating of at least 105 ˚C.