11

1.800.627.4499

Integral Indirect Gas-Fired Heat Module

OPTION

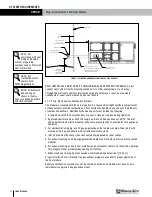

FIGURE 2.1.0 INDOOR VERTICAL VENTING FOR FLUE EXHAUST

-

-

-

RenewAire LLC

SCALE:1:30

SIZE

DWG. NO.

A

-

-

BY

DATE

--

Vent FEB19

10/29/18

AND TOL. ANSI Y14.5

CAH

SURFACE FINISH =

FINISH:

DESCRIPTION OF REVISION

TITLE:

LEVEL

DN-3-IN GH SEPARATED VERTICAL VENT

TOLL FREE: (800) 627-4499

--

DATE:

CHECKED BY:

3

REMOVE ALL BURRS, BREAK

63 MICROINCH MINIMUM

MATERIAL:

DATE:

SEE BILL OF MATERIAL

SHARP EDGES.

DO NOT SCALE DRAWING.

DRAWN BY:

SHEET 1 OF 1

DN IN GH Separated Vert

APPLICABLE STANDARDS: DIM.

UNLESS OTHERWISE SPECIFIED,

DIMENSIONS ARE IN INCHES.

TOLERANCES:

LINEAR 0.015

HOLE SIZE 0.005

ANGULARITY

4510 Helgesen Dr.

Madison, WI 53718 USA

TEL: (608) 221-4499

FAX: (608) 221-2824

SEE BILL OF MATERIAL

Roof Deck

Vent Terminal(s)

Listed Vertical

(Both Pipes)

Exhaust Vent

Cleanout Cap

Tee Fitting with

Drip Leg and

Combustion Air

Inlet

Min.

Min.

(0.75m)

expected snow depth.

Adjoining Building

Note: Provide sufficient

2.5 ft

clearance (height) to exceed

18 in.

(0.46m)

6 ft.

(1.8m)

Min.

To Wall or

18 in.

(0.3m)

Min.

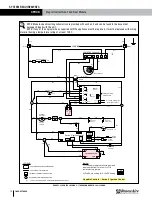

2.1.2.2 Horizontally Vented Heat Modules

Pressures in Category III venting systems are positive and therefore care must be taken to avoid

flue products from entering the heated space. Use only vent materials and components that are

UL listed and approved for Category III venting systems.

All vent pipe joints must be sealed to prevent leakage into the heated space. Follow instruction

provided with approved venting materials used. The proper vent pipe diameter must be used, to

insure proper venting of combustion products.

The total equivalent length of vent pipe must not exceed 50 feet [15.25 m]. Equivalent length is

the total length of straight sections, plus 5 feet [1.52 m] for each 90˚ elbow and 2.5 feet [0.76

m] for each 45˚ elbow.

The vent system must also be installed to prevent collection of condensate. Pitch horizontal pipe

runs downward ¼ inch per foot [21mm/meter] toward the outlet to permit condensate drainage.

Insulate vent pipe exposed to cold air or routed through unheated areas. Insulate vent pipe runs

longer than 10 feet (3m). Insulation should be a minimum of ½ inch [12mm] thick foil faced

material suitable for temperatures up to 500˚F [260˚C]. Maintain 6 inch [152 mm] clearance

between vent pipe and combustible materials.

A vent cap listed for horizontal venting must be provided. Vent cap inlet diameter must be same

as the required vent pipe diameter. The vent terminal must be at least 12 inches [305 mm]

from the exterior wall that it passes through to prevent degradation of building material by flue

gases. The vent terminal must be located at least 1 foot [305 mm] above grade, or in snow

areas, at least 3 feet [1 m] above snow line to prevent blockage. Additionally, the vent terminal

must be installed with a minimum horizontal clearance of 4 feet [1.2 m] from electric meters,

gas meters, regulators or relief equipment.

NOTE: For

assistance with vent

sizing and design,

contact a reputable

company such as Precision

Vent or Tjernlund.

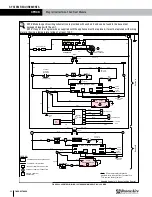

NOTE: All

installations must

comply with

SMACNA guidelines.

NOTE: All ductwork

and venting as

shown in illustra-

tions is supplied by others

and field-installed.

NOTE: A field-sup-

plied and installed

power vent may

be required for vent runs

longer than 50 equivalent

feet [15.25 m].

SYSTEM REQUIREMENTS