33

1.800.627.4499

Integral Indirect Gas-Fired Heat Module

OPTION

All piping should be clean and free of any foreign material. Foreign material entering the gas

train can cause damage.

IMPORTANT

DO NOT connect the module to gas types other than what is specified and DO NOT connect

the unit to gas pressures that are outside the pressure range shown on the unit label.

IMPORTANT

Before applying gas to the valves, test the gas pressure to make sure it is less than 13.5

InWC. Pressures greater than 13.5 inches WC will damage the gas valves.

IMPORTANT

INSTALLATION

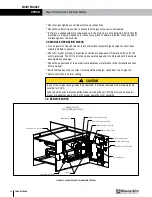

5.8.2 Determine Gas Supply Requirements

The data sticker located on the outside of the unit lists the requirements for the gas being

supplied to the unit.

FIGURE 5.8.0 TYPICAL DATA LABEL

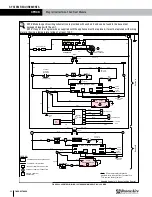

Ground

Joint

Union

8 in. Trap

Gas to

Controls

From Gas Supply

Bleeder Valve or

1/8 in Plugged Tap

Gas Cock

FIGURE 5.8.1 TYPICAL GAS SUPPLY PIPING CONNECTION

TYPE OF GAS REQUIRED

MINIMUM PRESSURE

REQUIRED

NOTE: When

connecting the gas

supply, the length

of the run must be

considered in determin-

ing the pipe size to avoid

excessive pressure drop.

Refer to a Gas Engineer’s

handbook for gas pipe

capacities.

NOTE: Gas heat

modules 50

MBH–100 MBH have

a single 1/2" NPT gas

connection. Gas heat

modules 125–350 MBH

have a single 3/4" NPT gas

connection.

All gas piping must be installed in accordance with the latest edition of the National Fuel Gas

Code, ANSI Z223.1 and any local codes that may apply. In Canada, the equipment shall be

installed in accordance with the Installation Code for Gas Burning Appliances and Equipment,

(CGAB 149) and Provincial Regulations for the class. Authorities having jurisdiction should be

consulted before installations are made.

IMPORTANT