29

1.800.627.4499

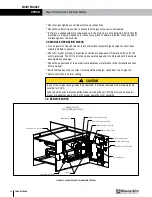

Integral Indirect Gas-Fired Heat Module

OPTION

4.8 DEFINITIONS FOR GAS HEAT MODULE

Heater Type:

HM—indirect gas-fired duct furnace from

50 MBH up to 350 MBH

Input Capacity:

MBH—BTU per hour (÷1000) rating for

furnace input capacity.

Input capacities are 50, 75, 100, 125,

150, 200, 250, 300, and 350.

Fuel Type:

Natural Gas (Standard)—natural gas used

in most applications.

Propane (Option)—propane available.

Tube Material:

409 Stainless Steel (Standard)—provides

excellent corrosion resistance at elevated

temperatures and is more corrosion-

resistant than aluminized steel.

304 Stainless Steel (Option)—higher

chromium and nickel content than 409

stainless steel with superb corrosion

resistance at elevated temperatures.

Airflow Orientation:

Horizontal—module installed where

airflow in ductwork is horizontal through

the heater.

Thermal Efficiency:

80% Efficiency—standard thermal

efficiency for gas-fired heat module.

Thermal efficiency is ratio of output

capacity to input capacity.

Elevation:

0-2000 feet (Standard)—module burner

orifices for operation up to 2000 ft. above

sea level.

2001-6999 feet (Option)—module burner

orifices for operation 2001-6999 ft. above

sea level.

Above 7000 feet (Option)—module burner

orifices for operation over 7000 ft. above

sea level.

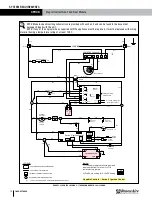

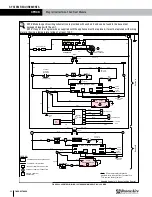

System/Inducer Voltage:

Single Phase—115V

Voltage Phase:

Single Phase only.

Control Voltage:

24 VAC (Standard)—secondary voltage

Control Type:

Modulating 5:1 Turndown (3:1 turndown

for propane)—module operates from

20-100% of output capacity based on

0-10Vdc input.

Modulating 10:1 Turndown—(6:1

turndown for propane) module operates

from 10% - 100% of output capacity

based on 0-10 VDC input.

Automatic Reset Fixed Temperature High

Limit Switch: (Standard)

Automatic reset limit switch included for

primary over-temperature protection.

Required by safety certifying agencies.

Combustion Air Pressure Switch:

(Standard)

Combustion air pressure switch included

to prove sufficient air flow is present.

Required by safety certifying agencies.

Manual Reset Flame Rollout Switch:

(Standard)

Manual reset flame rollout switch

included to monitor presence of burner

flame. Required by safety certifying

agencies.

Direct Spark Ignition Control (Standard):

Direct spark ignition control monitors Call

For Heat and ensures draft inducer fan is

operating before spark commences and

gas valve is energized for the ignition

period. Once burner ignites and cross

light and flame is detected, spark is

shut off. During heating operation, the

pressure switch and main burner flame is

constantly monitored for proper operation.

TECHNICAL DATA