16

Hydraulic connections

The hydraulic connections are located on the back of

the units.

The RKW 1000 and 1600 INOX units are ready to be

connected upon shipment.

For the RKW 2600, 3600 and 4500 INOX units, it is

possible to separate the plate heat exchanger of the

chiller and the storage module mounted underneath this.

For the RKW 2600 INOX unit, the plate heat exchanger

and the storage module are connected hydraulically by

the pipe connection installed at the factory.

For the RKW 3600 and 4500 INOX units, the plate heat

exchanger and the separately ordered storage module

must be connected upon assembly with the supplied

pipe connection. If the module is set up separately, the

necessary connection line must be installed by the cus-

tomer

The RKW 8000 and 9800 INOX units in this series are

supplied without hydraulics. The required components

are selected by the person who develops the system.

General information

◊

We recommend equipping the connections with

shut-off valves for service purposes.

◊

Additional, automatic ventilation valves must be

mounted at the highest location of the installation in

the supply and discharge pipes.

◊

To prevent vibrations from being transferred, com-

pensators (flexible lines) should be used between

the fixed pipe installation and the chiller.

◊

All pipe lines must be insulated to protect them from

condensation. According to the HeizAnlV (German

Heating Systems Ordinance), a 50% insulation di-

ameter must be planned for cooling mode and a

100% insulation diameter for cooling and heating

mode.

◊

To prevent the unit from becoming dirty, a water filter

(approx. 16 meshes pro cm²) should be installed in

the discharge line.

◊

The water pipes may not exert any static strain on

the chiller.

◊

A second key or pliers must be used to mount the

pipe lines on the RKW so as not to create any strain

on the pipe lines in the inside of the unit.

◊

If the chiller is only initially operated with a single part

of the overall system, the flow rate of the missing

system parts must be stimulated by pipe regulating

valves.

◊

To increase the run time of the unit, we recommend

using a storage module or cold water pipes that are

slightly larger to increase the volume if the necessary

capacity of the inner units is considerably smaller

than the cooling capacity of the chiller.

◊

The hydraulics must be set up in such a way that the

predefined minimum flow rate is reached.

Model

Water

incoming

outgoing

1000 INOX

1 ¼ ‘‘ inside 1 ¼ ‘‘ inside ½ ‘‘ outside

1600 INOX

1 ¼ ‘‘ inside 1 ¼ ‘‘ inside ½ ‘‘ outside

2600 INOX

1 ¼ ‘‘ inside 1 ½ ‘‘ inside

½ ‘‘ outside

3600 INOX

2 ‘‘ inside

2 ‘‘ inside

-

4500 INOX

2 ‘‘ inside

2 ‘‘ inside

-

3600 INOX with

storage module

2 ‘‘ inside

2 ‘‘ inside

½ ‘‘ outside

4500 INOX with

storage module

2 ‘‘ inside

2 ‘‘ inside

½ ‘‘ outside

8000 INOX

2 x 2 ‘‘inside

2 x 2 ‘‘ in-

side

-

9800 INOX

2 x 2 ‘‘inside

2 x 2 ‘‘ in-

side

-

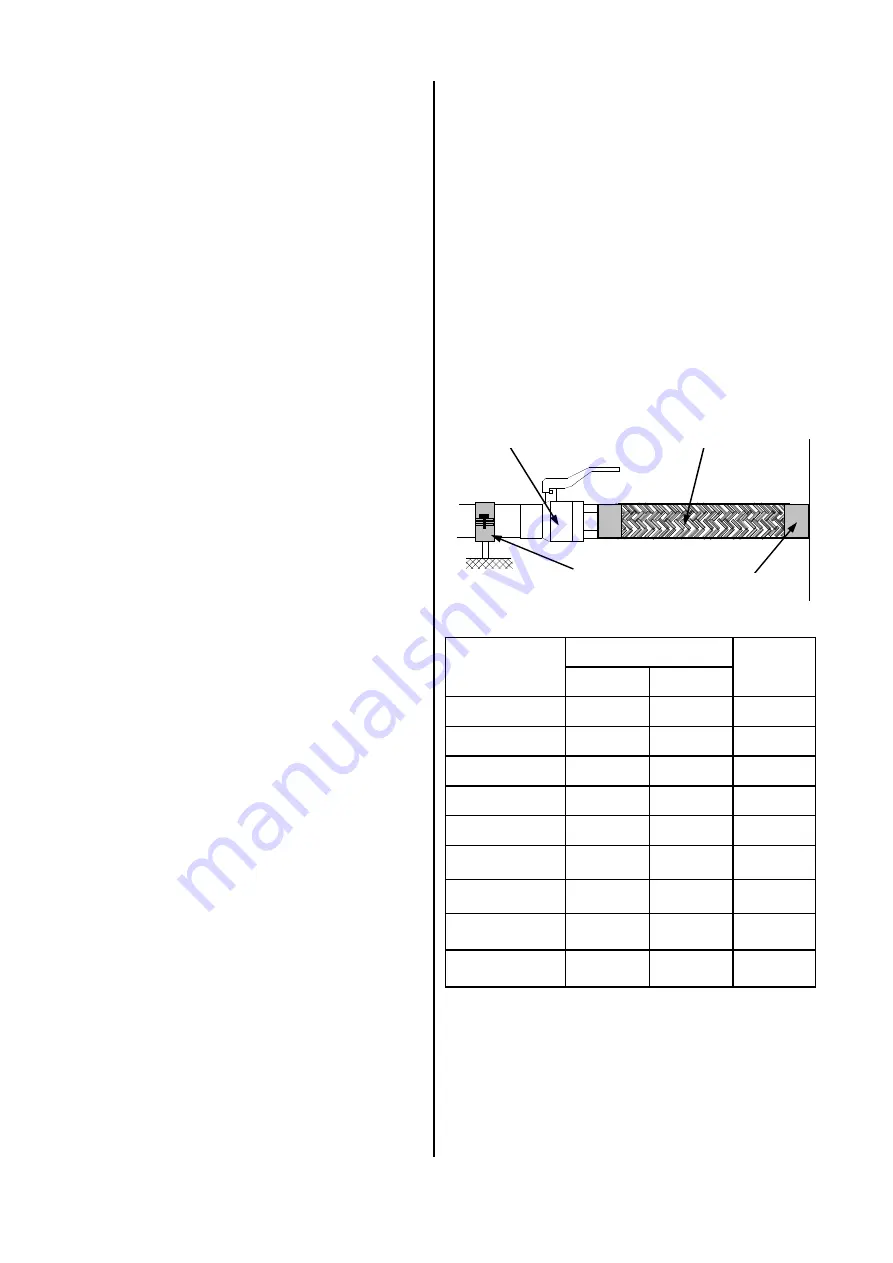

Filling con-

nection

Shut-off valve

Compensator

Static attachment

RKW connection

Connecting the water pipes

The RKW 1000, 1600 and 2600 INOX models in this

series are equipped with a cold water storage module

as a compact unit. The 3600, 4500, 8000 and 9800

INOX models are supplied in this series without hydrau-

lics for technical reasons. The water components in-

cluding the plate heat exchanger and the differential

pressure monitor are located in the chiller. The hydraulic

connections are found on the backs of all units.

For models RKW 3600 and 4500 INOX and higher, a

separate storage module can be mounted underneath

the chiller or somewhere else (e.g. inside the building).

So as not to transfer the vibrations of the chiller to the

system parts, the lines are connected to the unit by

compensators (flexible lines). We recommend equip-

ping the connections with shut-off valves for service pur-

poses.