11

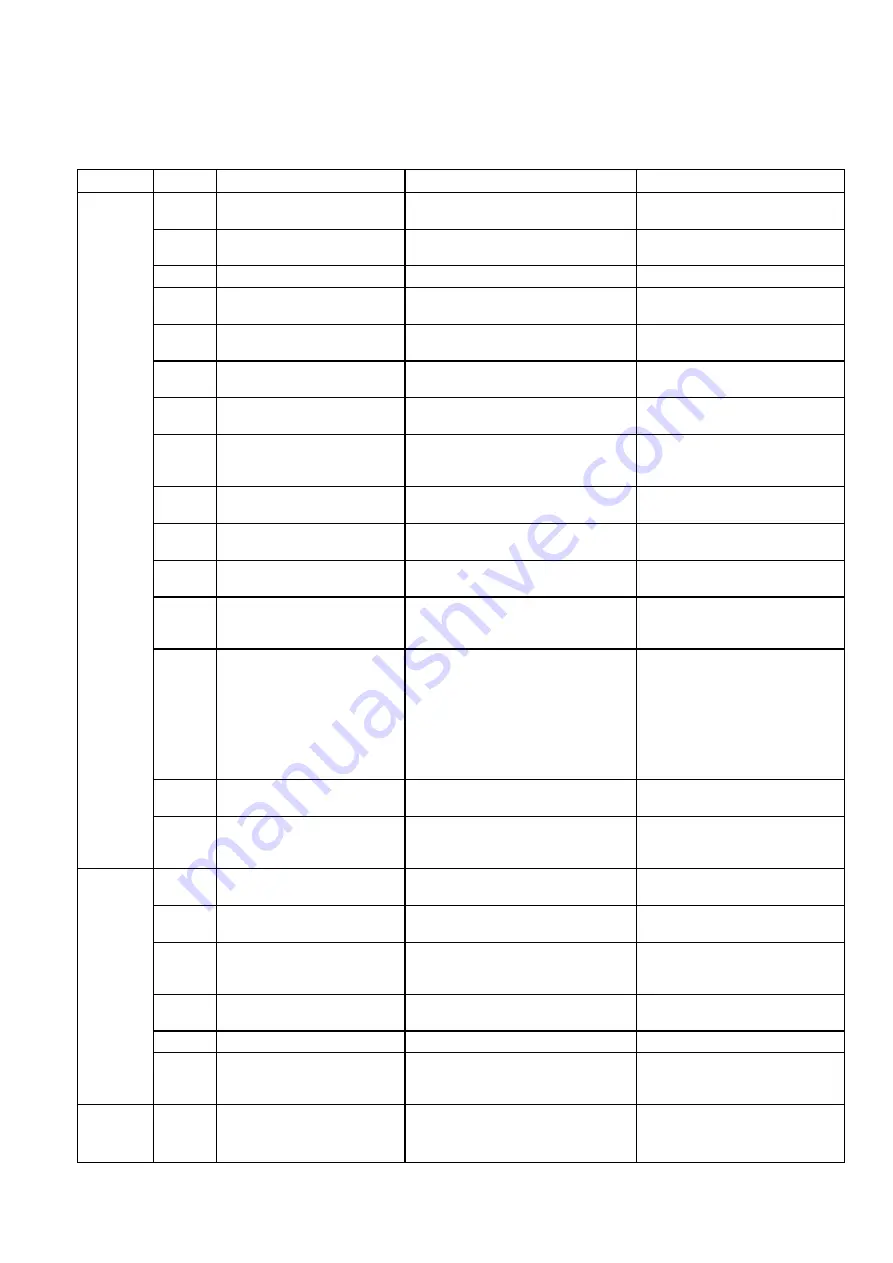

Troubleshooting

This unit has been designed based on state-of-the-art manufacturing methods and it has been tested repeatedly to

ensure that it is working properly. However, should problems occur, refer to the following list.

Problem

Alarm

Possible cause

Check

Remedy

The unit

does not

start or it

switches

itself off

automati-

cally.

Power failure

Are all other electrical components

working?

Check voltage and wait for the

unit to start again.

Power fuse / power supply de-

fective

Are all other electrical components

working?

Maintenance by authorised

personnel

Waiting period too short

Is the COMP LED blinking?

Schedule longer waiting periods

Regulation is not working

Is the LINE LED and to the

COOL LED lit up?

Connect current and select the

COOL operating mode

Incorrect discharge tempera-

ture or parameter setting

Check setting

Change setting

E01/E02

E21/E22

High-low pressure alarm

Are the fans rotating?

Is the pressure in the cold cycle OK?

Have checked by authorised

company

E00/E21

Remote control / Connection

to C2-DIN defective

Is the display working?

Is the connection OK?

Replace remote control or re-

establish connection between

CH-DIN and C2-DIN

E03/E23 Compressor overheating

Is the temperature of the compressor

above approx. 100 °C?

Maintain operating ranges, clean

fins

E04/E24

Liquefaction temperature too

high

Are the fins clean and have the oper-

ating ranges been maintained?

Clean fins, place unit in the

shade

E05/E25 Frost protection activated

Is the supply temperature 4°C or

lower?

Increase discharge temperature

E06/E07/

E26/E27/

E40

Sensors defective ST1 to ST6

It is the alarm activated when the

sensor is replaced?

Replace defective sensors

E41

Flow switch (differential pres-

sure monitor) activated

Are the following values OK:

◊

Volume of current (too large/small)

◊

No air in the monitoring pipes

◊

Circulation pump

◊

Does the monitor switch on and off

◊

Stop mechanisms are open

◊

Water pressure too high/low

Have checked by authorised

company

E42

Hardware defective

Does the regulation function

smoothly?

Have regulation replaced by

authorised company

Compressor contact defective

Is the COMP LED lit up and is there

current on the contact?

Have the contact or compressor

replaced by an authorised com-

pany

The unit is

either not

cooling at

all or only

a little bit

Heating capacity was in-

creased

Has there been a structural change? Maintain safety zones

Supply temperature too high

Is the supply temperature approx.

5 ... 10 °C?

Reduce discharge temperature

Air in the system

Have automatic ventilators been

mounted on the highest possible po-

sition?

Ventilate manually or integrate

ventilators

Liquefaction temperature too

hot

Are the fins clean and have the oper-

ating ranges been maintained?

Clean fins, place unit in the

shade, maintain operating ranges

Incorrect parameter settings

Check settings

Change settings

Sporadic operation because

cooling requirements are too

low

Has the system been designed for

smaller measurements?

Increase the quantity of water by

installing a storage module

Water

leaks out

of the unit

Leaks in pipes or defective in-

sulation

Are there leaks and have all lines

been insulated?

Seal and insulate

Incorrect electrical rotational

direction

Did the phase-sequence relay switch

through?

Change the rotational direction