REHAU has performed extensive testing of RAUPEX pipes exposed to

UV, leading to the maximum UV exposure times expressed in

accumulated days. Once the pipes leave the manufacturing plant, any

exposure to UV, including transportation and storage, is part of the

accumulated exposure time.

Although ASTM F876 only categorizes up to 6 months of UV resis-

tance (Material Designation Code = 3

3

06), REHAU has tested and

certi

fi

ed RAUPEX white UV shield pipe according to ASTM F2657 for

the following maximum UV exposure period:

- RAUPEX white UV shield pipe: Maximum exposure time of one year

accumulated

RAUPEX pipes must be kept in the original packaging until the time of

installation. RAUPEX must not be stored outdoors and is not designed

for permanent outdoor exposure (with the exception of non-exposed

buried applications).

NOTICE

Failure to follow maximum UV exposure limits may damage the pipe

resulting in leaks and operational failures, and will negate any

warranty provided by REHAU for RAUPEX pipes.

4.9 Bend Radius

RAUPEX pipe may be bent, even when cold. REHAU support bends

can assist to create tight bends without kinking. The typical bend

radius used by the installer is 8X the OD. The minimum bend radius is

5X the OD for cold bends. For an even smaller bend radius, the pipe

may be heated with a heat gun and bent to no less than 3X the OD. If

a tighter bend radius is required, the designer should consider using a

smaller diameter pipe.

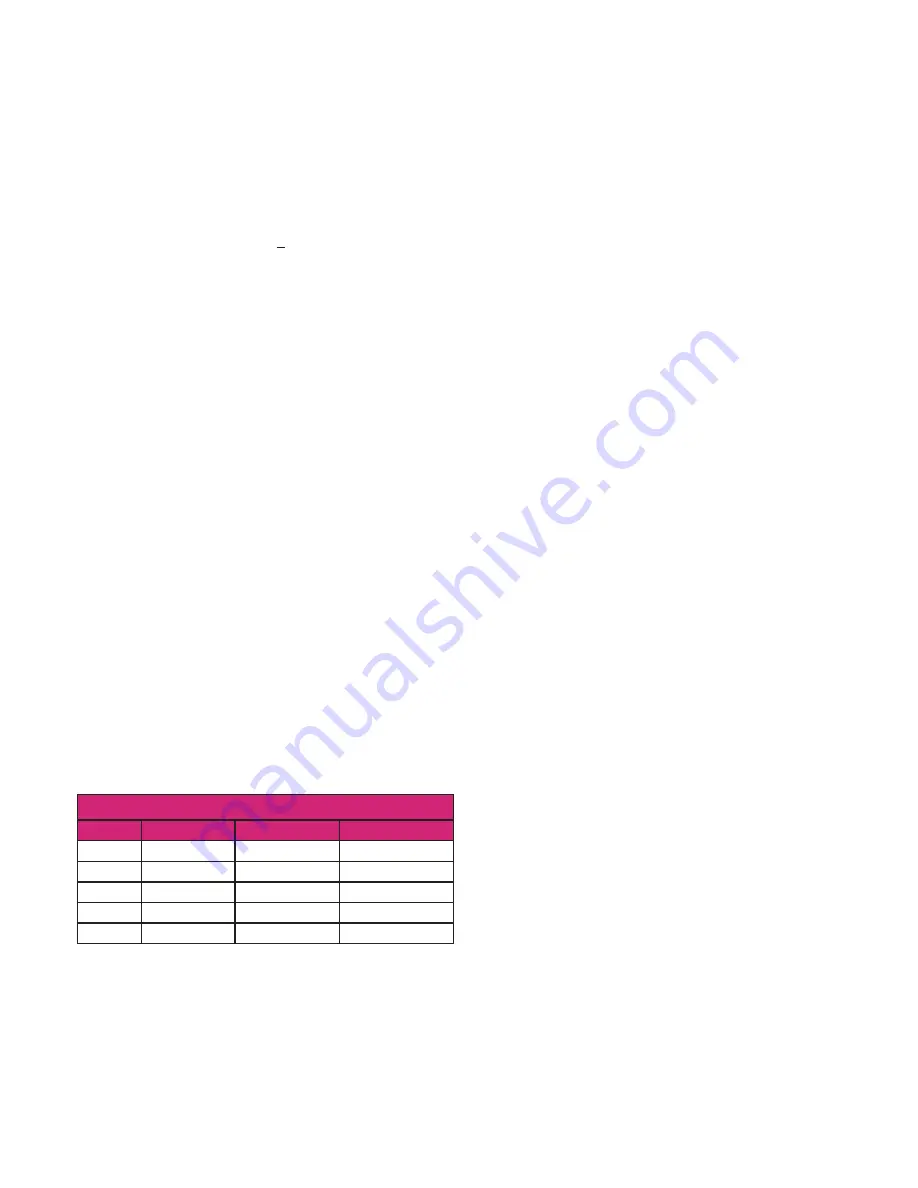

Table 4.4: RAUPEX Bend Radius

Bend Radius in (mm)

Pipe Size

Typical 8X OD

Min. Cold 5X OD

Min. Heated 3X OD

3/4 in

7.0 (178)

4.375 (111)

2.625 (67)

1 in

9.0 (229)

5.625 (143)

3.375 (86)

1 1/4 in

11.0 (279)

6.875 (175)

4.125 (105)

1 1/2 in

13.0 (330)

--

--

2 in

17.0 (432)

--

--

4.10 Chemical Compatibility

While RAUPEX pipes are resistant to many chemicals that are used in

typical residential

fi

re sprinkler applications, there are some chemicals

that may damage the pipe.

Chemicals that may be damaging include (but are not limited to):

- Adhesives

- Oil or petroleum-based products

- Paints

- Solvents

- Oxidizing agents

- Disinfectants

- PVC glues

- Solvents and cements

Many factors, such as exposure time, temperature, pressure and other

operating parameters, can in

fl

uence the performance of a pipe that is

exposed to a chemical. To determine the impact of a particular

chemical, short- and long-term pressure testing may be required. In

some cases, a pipe may be resistant to short-term exposure to the

chemical, but not resistant to continuous exposure. Each chemical

must be evaluated individually. It is the responsibility of the installing

contractor to verify chemical compatibility of any chemicals when

coming into contact with the polymer material.

4.11 Freeze Break Resistance

The

fl

exibility of the RAUPEX pipe allows it to expand as water freezes

in the pipe as long as the pipe has room to expand. When the water

thaws, the pipe returns to its original shape. If the pipe is not allowed

to expand (e.g., it is encased in concrete), it may burst.

NOTICE

Designers and installers must take precautions as per the guidelines

de

fi

ned in NFPA 13D to ensure that pipes do not freeze. Frozen pipes

may burst resulting in leaks and operational failures.

4.12 Condensation

Condensation occurs on pipes when the surface temperature is lower

than the dew point of the environment. This is typically a problem for

metallic cold water piping. PEX pipe has a lower thermal conductivity

(0.41 W/m°K) than copper (401 W/m°K) resulting in less heat loss to

the surface and greater resistance to condensation or sweating.

10