14

Principles of Operation

The RBD Model 04

-

165 2 kV Backfill Ion Source is used with the RBD Model 32

-175 Ion Source

Control. Together with the appropriate gas admission system such as the RBD IG2

-

AGA, these

units comprise

a

complete

system

designed

to sputter-

etch

a

specimen

surface

using

inert-

gas

ions.

The

ion

gun is CF flange mounted and can be installed in standard vacuum systems. The

control unit contains all the electronics and power supplies necessary for operating the ion source.

The Model RBD Model 04

-

165 2 kV

Backfill Ion Source generates an energetic inert

-

gas ion

beam for

sputter-

etching

solid

surfaces.

In

operation,

the

test

chamber

is

backfilled

to

a

static

pressure

of

5 x

10

-5

torr

with

an

inert

gas

such

as

argon.

Positive

ions

are

created

by

electron

impact

within

the

ion

gun’s

ionization

chamber.

The

ions

are

then

extracted

from

the

ionization

chamber,

accelerated

through a focusing lens, and directed at a specimen with

energies up to 2 keV. The impurity content of the ion beam

is

minimized

because

there

is no

direct line

of

sight

from

the

hot

filament

to

the

target.

Operating

parameters

are

adjustable

on

the front

panel of

the

Model 32

-175 Ion Source Control. Focus,

beam voltage

selection,

filament

selection,

and

emission

are

all

controlled

by

the

ion

gun

control.

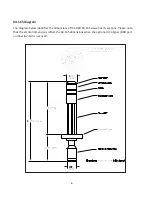

Appendix – Cable Diagrams

The

cable

diagram

for

the

cable

included

with

the

IG2

is

provided

in

this

appendix.

We

have

also

included cable diagrams for the optional cables that are available to integrate the RBD

04-

165 ion source with the PHI controller and the RBD 32

-17

5 ion source control with the PHI

ion guns

.