10

2.

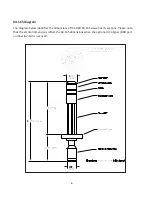

Remove

the

blank

flange

from

the

vacuum

chamber

port into

which

you

are

installing

the

ion

source.

3.

Insert

a new

copper gasket between

the ion source and the flange

.

4.

Tighten

the

ion source

flange

using

the

appropriate

hardware

.

5.

Bake the system at 150° C to 200° C for 4 to 8 hours. You may use heat tape to bake only the 04

-

165.

Install the 32-175 Ion Source Control

1.

Mount

the 32

-

175 Control in a 19" electronics rack

or use on a desktop

(ensure power cable is

disconnected and power switch is off)

.

2.

Connect the 04

-

165 Ion Source to the 32

-

175 Control using the IG2

-

CA1 cable.

3.

C

onnect the AC power cord (120 VAC OR 230 VAC)

to the 32

-

175 and then plug the AC power

cord into the power outlet.

DO NOT TURN ON THE POWER to the 32-

175 at this �me

.*

4.

Set the following switches and controls on the 32

-

175 Control front panel:

a.

Set the Beam Control switch to Off.

b.

Set the Beam Voltage Select dial to 500, which is its lowest se�ng.

c.

Turn the Focus Adjust dial arrow to center (straight up).

d.

Turn the Filament Adjust dial fully counterclockwise

(set to 0).

5.

On the 32

-

175 Control back panel, set the Filament Select Switch (labeled F1 and F2) to the F1

posi�on.

6.

The IG2 is now ready for use.

*

It is recommended that the AC power to the 32-175 is interlocked to your ion gauge so that

the 32-175 cannot be turned on if your vacuum chamber is up to air.

Remote Switching of the Ion Beam

If you want to use a computer to control the ion gun beam remotely, you need to connect a TTL

level BNC cable to the Remote connector on the back of the 32

-175. A

TTL

low

turns the beam volt

-

age

ON

,

and

a

TTL

high

will turn

the

beam

voltage

OFF

.

The

Remote

signal

only

turns the beam

voltage on and off. The filament is controlled independently.