21

CAUTION:

Combustion air must not be contaminated

by corrosive chemical fumes which can damage the

heater and void the warranty.

Potable Water and Space Heating

1. All piping materials and components connected to

the water heater for the space heating application

shall be suitable for use with potable water.

2. Toxic chemicals, such as used for boiler treat-

ment, shall not be introduced into the potable

water used for space heating.

3. If the heater will be used to supply potable water,

it shall not be connected to any heating system or

components previously used with a non-potable

water heating appliance.

4. When the system requires water for space heat-

ing at temperatures higher than 140°F (60°C), a

means such as a mixing valve shall be installed to

temper the water in order to reduce scald hazard

potential.

Automatic Chemical Feeders

All chemicals must be introduced and completely dilut-

ed into the water before being circulated through the

heater. High chemical concentrations will result when

the pump is not running (e.g. overnight).

CAUTION:

When this heater is used for both potable

water and space heating, observe the following to

ensure proper operation.

NOTE:

Failure of a heat exchanger due to lime scale

build-up on the heating surface, low pH or other

chemical imbalance is non-warrantable.

NOTE:

High chemical concentrates from feeders

that are out of adjustment will cause rapid corrosion

to the heat exchanger. Such damage is not covered

under the warranty.

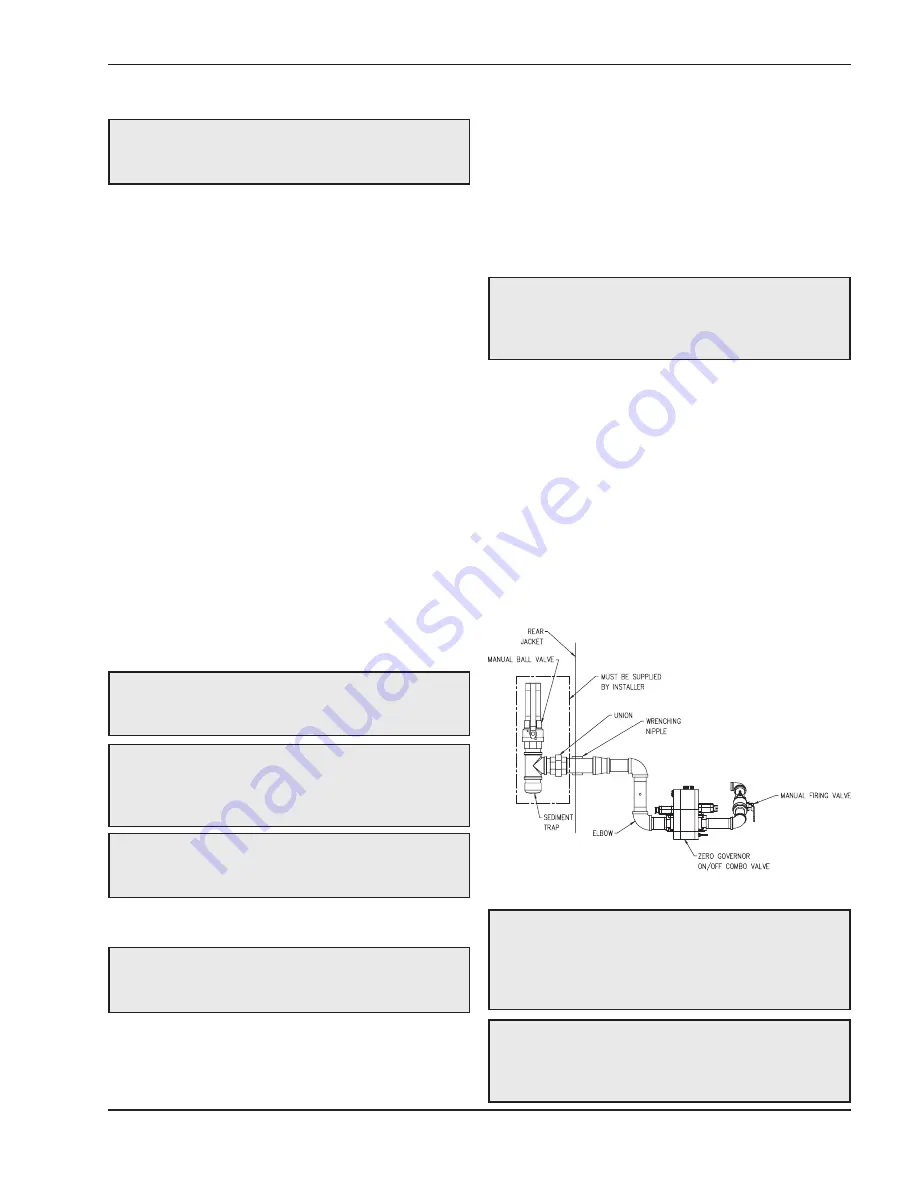

Gas Supply

Gas piping

must

have a sediment trap ahead of the

heater gas controls,

and

a manual shut-off valve

lo-cated outside the heater jacket. It is recommend-

ed that a union be installed in the gas supply piping

DANGER:

Make sure the gas on which the heater

will operate is the same type as specified on the

heater’s rating plate.

adjacent to the heater for servicing. The gas supply

pressure to the heater must not exceed 10.5 in. WC for

natural gas or 13.0 in. WC for propane gas. A pounds-

to-inches regulator must be installed to reduce the gas

supply pressure if it is higher than noted above. This

regulator should be placed a minimum distance of 10

times the pipe diameter upstream of the heater gas

controls. Refer to Table I for maximum pipe lengths.

Gas Supply Connection

The heater must be isolated from the gas supply piping

system by closing the upstream manual shut-off valve

during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psi

(3.45 kPa). Relieve test pressure in the gas supply

line prior to re-connecting the heater and its manual

shut-off valve to the gas supply line.

FAILURE TO

FOLLOW THIS PROCEDURE MAY DAMAGE THE

GAS VALVE

. Over-pressurized gas valves are not

covered by warranty. The heater and its gas connec-

tions shall be leak-tested before placing the appliance

in operation. Use soapy water for leak test. DO NOT

use an open flame.

CAUTION:

The heater must be disconnected from

the gas supply during any pressure testing of the

gas supply system at test pressures in excess of 1/2

psi (3.45 kPa).

Fig. 23: Gas Supply Connection

CAUTION:

Do not use Teflon tape on gas line

pipe thread. A pipe compound rated for use with

natural and propane gases is recommended. Apply

sparingly only on male pipe ends, leaving the two

end threads bare.

CAUTION:

Support gas supply piping with hangers,

not by the heater or its accessories. Make sure the

gas piping is protected from physical damage and

freezing, where required.

Содержание XTherm 2505

Страница 2: ...2 Rev 2 reflects the following Changes to Additions Deletions ...

Страница 46: ...WIRING DIAGRAM Models 2505 4005 46 For a full size drawing visit www raypak com commercial wiring_diagrams ...

Страница 61: ...61 ...

Страница 62: ...62 ...

Страница 63: ...63 ...

Страница 64: ...64 ...

Страница 65: ...65 ...

Страница 66: ...66 www raypak com Raypak Inc 2151 Eastman Avenue Oxnard CA 93030 805 278 5300 Fax 805 278 5468 Litho in U S A ...