Vector Solo Waterborne Applicators - Maintenance

35

Ransburg

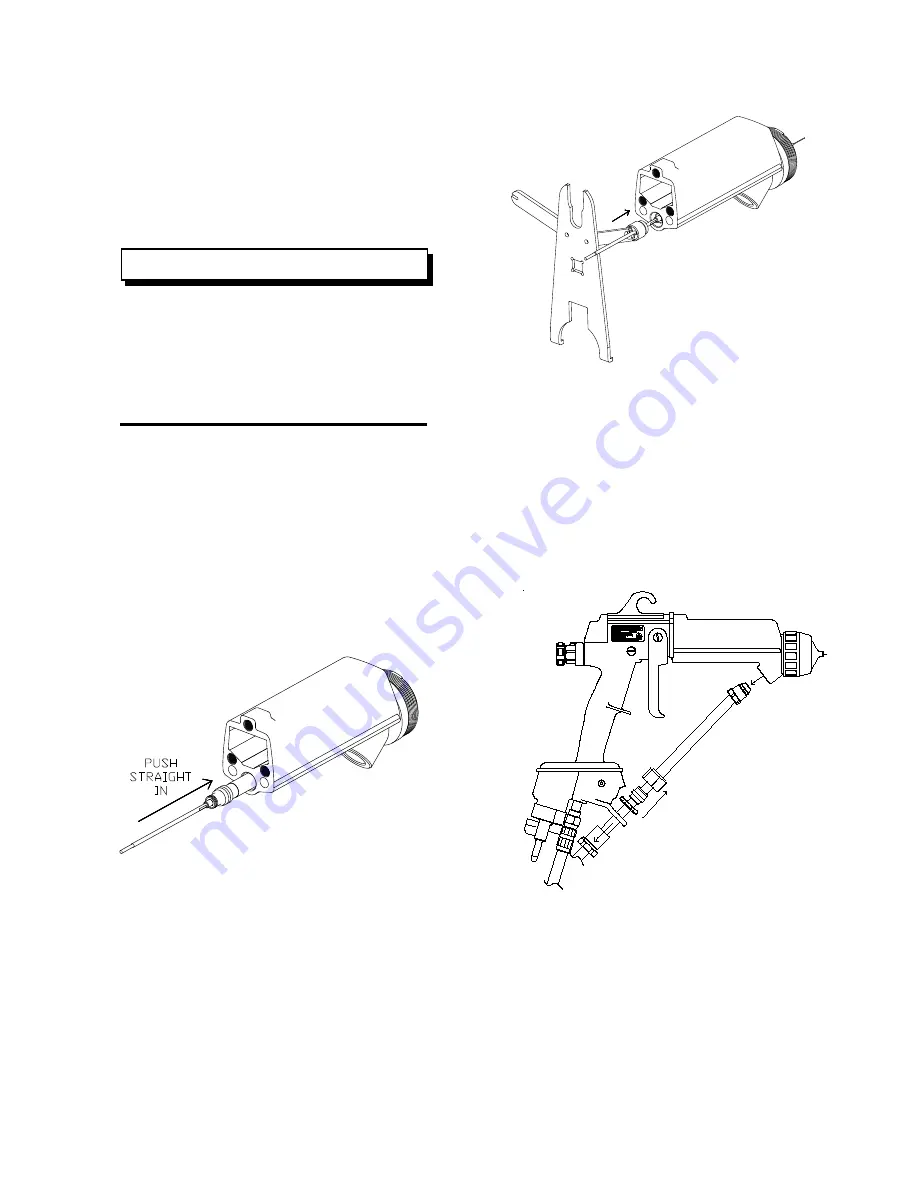

2. Tighten rear nut using Special Wrench 79854-

00. Tighten until drag is felt on the shaft when it is

pushed back and forth.

Figure 48: Adjustable Needle Shaft

Reinstall Needle Shaft / Barrel

1. Push needle shaft assembly straight into the

barrel. Apply Dielectric Grease LSCH0009-00.

Figure 47: Needle Shaft Replacement

3. Reinstall cascade.

4. Reinstall barrel to handle.

Power Module Removal

1. Remove the fluid line

Figure 49: Fluid Line Removal

Be generous with the dielectric grease

when applying it to the packing tube and

needle shaft. This helps to remove air

voids from this chamber.

DO NOT

apply

so much grease that it creates an air lock

during assembly of the applicator.

NOTE

5. With your finger, wipe the excess grease from

both ends of the packing tube. Using the excess

grease, apply a thin film to the outer surface of

the packing tube and to the external o-ring on the

cartridge seal.

6. Apply a light film of dielectric grease to the seal

retainer o-ring and install it into the external groove.

AH-08-03.6