1.0. IMPORTANT SAFETY REQUIREMENTS

a-

This equipment is for professional use only. Observe all warnings. Read and understand all

instruction manuals, warning labels, and tags before you operate the equipment.

b-

CAUTION: This manual contains important instructions and safety cautions on

diaphragm pumps. Read and understand all of it before first use of the pump.

Manufacturer is not responsible for damages and injuries caused by inappropriate

usage of the pump.

c-

Diaphragm pump usage is limited to within

the area defined in this manual. Refer to GİSAN

for any further questions.

d-

Never let unqualified / unauthorized people operate a diaphragm pump

.

e-

Never alter or modify any part of this equipment; doing so could cause it to malfunction. Use

only genuine RAN™ Pump parts and accessories.

f-

Illuminate the environment thoroughly for proper usage and maintenance of the equipment.

g-

Do not make changes to the pump that may affect its working systems.

h-

Pump maintenance and repair should only be carried out by qualified personnel.

i-

Do not surpass the strength of minimum system compound.

j-

Learn hazards or potential dangers of your fluid.

k-

Choose the wet pump parts’ material resistant to your fluids. Refer to the Proper Material-

Fluid Chart or your supplier for further information.

l-

Use an approved container for the hazardous media.

m-

Do not pull the pump by the hoses.

n-

Do not let the hoses twist.

o-

Make sure that hose connections to the pump are tight to avoid air suction.

p-

Do not lift or move the pump while it is pressurised.

r-

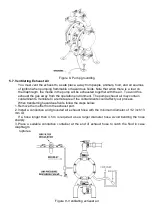

If you are working with flammable or toxic fluids, be sure the system is properly ventilated for

your type of installation. You must vent the exhaust to a safe place, away from people,

animals, food, and all sources of ignition when pumping flammable or hazardous fluids. Note

that when there is tear on the diaphragm, the media in the pump will be exhausted together

with the air. Refer to the Figure 9 Air Exhaust.

s-

Diaphragm pumps in this technical file are sold only as a pump unit. Control unit is not

supplied with the pump. Operator is responsible for installing a suitable control system if

needed.

t-

Tightly connect the proper hose for your media to one end of the pump and the other to the

tank where the media will be stored.

Содержание E40-SX

Страница 20: ...Figure 13a Pump assembly scheme for RAN 2...