12.0 ORDERING SPARE PARTS

No spare parts suppliedwith the diaphragm pump. Contact us using the details above to order.

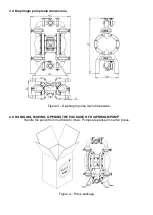

“Figure 13: Spare parts list for RAN 2” pump.

NOTE:Please state model number when ordering spare parts.

Diaphragm Part List Ball Part List

NOTE: Please refer to material codes above tables when ordering replacement Diaphragm,

Ball, and Ball Seat, bearing in mind the properties of the liquid to be transferred.

NO

CODE

PARTS

QTY

NO

CODE

PARTS

QTY

1

E1042 Center section

1

24

-

Valve fixing bolt

8

2

E1141 Shaft O-ring

2

25

E3341 Cover exhaust

1

3

E1241 Shaft seat

2

26

E1442 Shaft

1

4

E1342 Shaft cover

2

27

E1541 Flange O-ring

4

5

E1345 Pilot shaft cover

2

28

E1643 Diaphragm flange

4

6

-

Cap bolt

16

29

-

Back up Diaphragm

2

7

E2542 Pilot shaft seat

2

30

-

Diaphragm

2

8

B2611 Pilot shaft O-ring

6

31

-

Diaphragm clamp bolt

2

9

B2711 Pilot shaft cage

5

32

-

Diaphragm clamp washer

2

10

E2844 Pilot shaft

1

33

E1843 Body

2

11

B2911 Pilot shaft ring

2

34

-

Body fixing bolt

16

12

E3043 Valve

1

35

-

Body fixing washer

16

13

E3242 Valve cover

1

36

E3646 Leg

2

14

E3243 Valve cover O-ring

2

37

-

Body fixing nut

16

15

-

Valve cover bolt

6

38

-

Ball

4

16

E3144 Valve core

1

39

E8916 Manifold gasket

4

17

E3142 Valve Z-ring

2

40

E8817 Inlet elbow manifold

2

18

E3246 Valve button cover

1

41

E8917

Center manifold gasket

2

19

D3234 Valve button seal

1

42

E8818

Center manifold

2

20

E3245 Reset button

1

43

E8912

Center manifold clamp

4

21

E3145 Ventil

1

44

E8911

Manifold clamp

4

22

E3146 Ventil plate

1

45

E8816

Outlet elbow manifold

2

23

E3044 Valve gasket

1

46

E8918

Flange

2

No

Code

Part Material

1

E1740

Back up

2

E1741

NBR (Nitrile)

3

E1742

PTFE (Teflon)

4

E1743

Santoprene

5

E1744

Polyurethane

6

E1745

VITON

7

E1746

Neoprene

8

E1747

EPDM

9

E1748

Santoprene Back up

No

Code

Part Material

1

E2141

Polyethylene

2

E2142

PTFE (Teflon)

3

E2143

Delrin

4

E2144

Santoprene

Содержание E40-SX

Страница 20: ...Figure 13a Pump assembly scheme for RAN 2...