Maintenance

Before working on the attached implement, disengage the

power take-off shaft, switch off the engine and remove the

ignition key.

DO NOT work under a raised implement. If this is unavoid-

able, secure the implement to prevent it dropping by ac-

cident.

Use suitable tools and wear protective gloves when han-

dling cutting implements.

Before working on the hydraulic system (”Drill-Lift”), lower

the implement completely and release the hydraulic pres-

sure. Dispose of used oil and lubricants correctly (mineral-

based products only!).

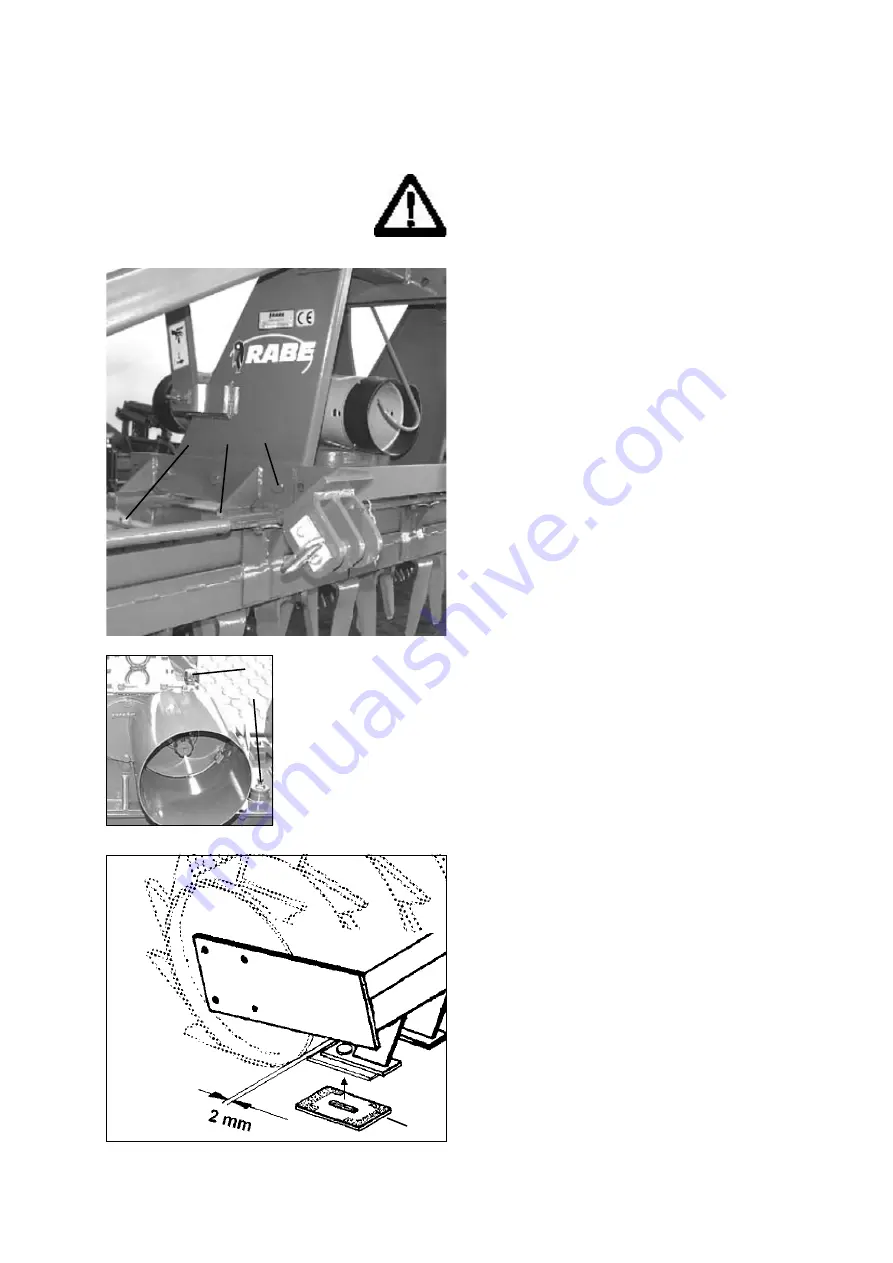

After about eight hours of initial use, check all screws

and bolts for tightness. Repeat this check at regular

intervals and tighten using a torque wrench.

The knife tine fixing bolts should be tightened to 380

Nm,

and the hitch attachment (

21/1

; M 20x1.5) to 650 Nm,

(

21/2

; M 12 - 12.9) - to 145 Nm,

cover bolts: (

21/3

; M 12 - 10.9) - 120 Nm.

Daily:

Check the level of transmission oil by insert-

ing the dipstick (

22/1

) as far as the thread, but without

screwing it in.

Weekly:

Check the level of liquid lubricant grease in

spur gear casing at nozzle (

22/3

; see also section on oil

changes).

Lubricate the bearings regularly with a grease gun applied

to the greasing nipples;

daily:

packer-roller bearings, at

”Drill-Lift” three-point linkage and drive shaft (including slid-

ing profiles).

Oil all linkages, ensure free movement of spindles.

Touch up any chipped or damaged paintwork.

Check the propeller-shaft overload clutch; ”air” the fric-

tion clutch if the implement has not been in use for a

long period.

Avoid directing the hose at the bearings for any length

of time when cleaning the implement with high-pressure

water.

Check the hydraulic hose (Drill-Lift) regularly for signs

of damage or brittleness and replace as required (see

list of spare parts). These hoses are subject to a natural

ageing process and should in any case be replaced

after 5-6 years, regardless of their apparent condition.

Toothed roller:

Readjust the scraper at regular inter-

vals. Push the scraper into slight contact with the roller.

When tightening the nuts, ensure that the scraper lies

parallel along its entire length.

Fit hard-coated scrapers (

23/1

) with the coated surface

facing upwards relative to the roller, at a distance of

about 2 mm from the roller.

The toothed roller is easy to keep clean if it is washed

down after each use and protected from corrosion.

22

1

3

21

1

23

11

1

2

3