Section VIII - Troubleshooting

Symptom/Probable Causes:

Corrective Action:

Quincy Compressor

®

- QSB/T

™

61

Compressor Does Not Unload When There Is No

Air Demand:

I

NCORRECT

AIR

PRESSURE

SWITCH

SETTING

F

AULTY

AIR

PRESSURE

SWITCH

F

AULTY

BLOWDOWN

VALVE

F

AULTY

SOLENOID

VALVE

F

AULTY

DIFFERENTIAL

PILOT

VALVE

L

EAKS

IN

CONTROL

LINES

L

EAKS

IN

SERVICE

LINES

Compressor Does Not Revert To Load When

Service Line Pressure Drops To Reset Pressure:

F

AULTY

AIR

PRESSURE

SWITCH

L

OOSE

WIRING

CONNECTION

J

AMMED

AIR

INLET

VALVE

ASSEMBLY

F

AULTY

SOLENOID

F

AULTY

TIMER

F

AULTY

DIFFERENTIAL

PILOT

VALVE

Compressor Will Not Time-out Or Shut Down

When Unloaded (Auto/Dual Only):

F

AULTY

TIMER

L

EAKS

IN

CONTROL

LINES

L

EAKS

IN

SERVICE

LINES

F

AULTY

AIR

PRESSURE

SWITCH

F

AULTY

AIR

PRESSURE

SENSORS

A

DJUST

TO

PROPER

SETTING

.

R

EPLACE

SWITCH

.

R

EPAIR

OR

REPLACE

AS

NECESSARY

.

R

EPAIR

OR

REPLACE

AS

NECESSARY

.

R

EPAIR

OR

REPLACE

AS

NECESSARY

.

C

HECK

ALL

CONTROL

LINE

FITTINGS

AND

TUBING

.

C

HECK

LINES

BEFORE

MPC

VALVE

.

R

EPAIR

OR

REPLACE

AS

NECESSARY

.

C

HECK

AND

TIGHTEN

WIRING

TERMINALS

.

C

HECK

AND

REPAIR

AIR

INLET

VALVE

.

R

EPAIR

OR

REPLACE

AS

NECESSARY

.

C

HECK

AND

REPLACE

TIMER

.

O

RIFICE

PLUGGED

. C

LEAN

OR

REPLACE

AS

NECESSARY

.

C

HECK

AND

REPLACE

AS

NECESSARY

.

C

HECK

AND

REPAIR

ANY

LEAKS

.

C

HECK

PLANT

AIR

DISTRIBUTION

SYSTEM

FOR

LEAKS

.

R

EPAIR

OR

REPLACE

AS

NECESSARY

.

R

EPLACE

AS

NECESSARY

.

Содержание QSB Series

Страница 2: ......

Страница 9: ...Section I General Quincy Compressor QSB T 5 MODEL IDENTIFICATION...

Страница 21: ...Quincy Compressor QSB T 17 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 27: ...Quincy Compressor QSB T 23 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 71: ...Quincy Compressor QSB T 67 THIS PAGE INTENTIONALLY LEFT BLANK...

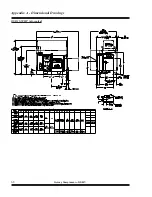

Страница 72: ...Appendix A Dimensional Drawings 68 Quincy Compressor QSB T QSB 15 50 HP air cooled...

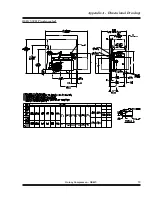

Страница 73: ...Appendix A Dimensional Drawings Quincy Compressor QSB T 69 QSB 15 50 HP water cooled...

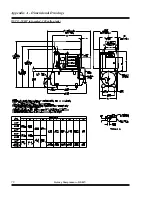

Страница 74: ...Appendix A Dimensional Drawings 70 Quincy Compressor QSB T QST 15 50 HP air cooled 120 gallon tank...

Страница 75: ...Appendix A Dimensional Drawings Quincy Compressor QSB T 71 QST 15 50 HP water cooled 120 gallon tank...

Страница 76: ...Appendix A Dimensional Drawings 72 Quincy Compressor QSB T QST 15 50 HP air cooled 200 gallon tank...

Страница 77: ...Appendix A Dimensional Drawings Quincy Compressor QSB T 73 QST 15 50 HP water cooled 200 gallon tank...