Section IV - Operating Procedures

Quincy Compressor

®

- QSB/T

™

19

Stopping the Compressor - Normal Operation

Close the service valve to the plant air distribution

system. Allow the pressure to build within the reservoir

and the compressor to fully unload. Turn selector switch

to the “OFF” position.

NOTICE!

Always close the service valve when the

compressor is not being used to prevent the

system’s air pressure from leaking back into the

compressor if the check valve leaks or fails.

Stopping the Compressor - Emergency

Press the emergency stop button or cut the power at the

main disconnect switch or panel.

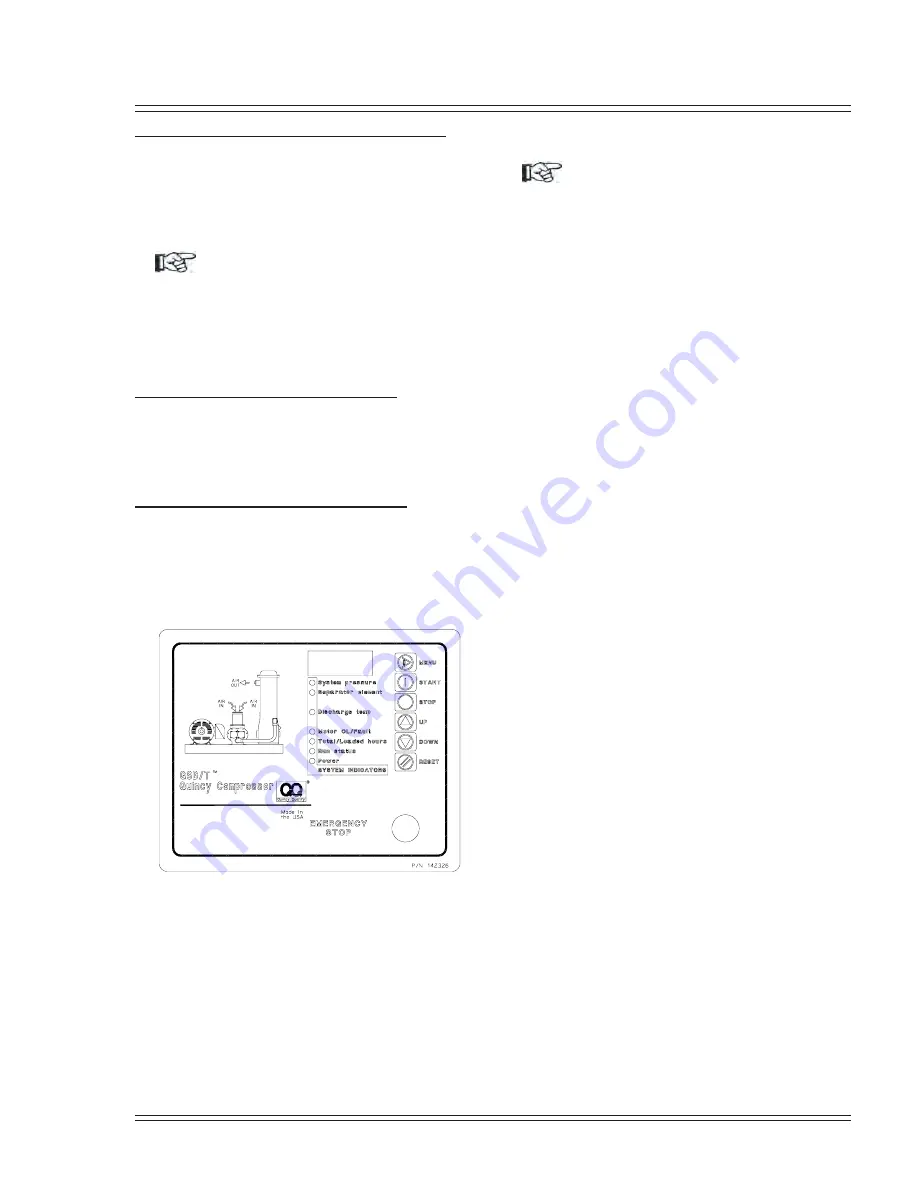

Electronic Control Operation (optional)

The decal below shows the control layout for the

electronic control panel. The primary controls are on the

right hand side of the panel, with the selected item being

displayed on the LED digits in the top window.

The LED lamps in a vertical column, show the selected

display parameter and/or any alarm conditions. On

applying system power the LED status lights will blink

and the numeric display will show the version number of

the software code installed. The system is ready to run

when the

Power

and

System pressure

LED lamps are lit

and the pressure is displayed in the numeric display.

NOTICE!

A flashing —— on the digit display, accompanied

by an LED on the left, signifies a faulty sensor

(either the pressure transducer or the temperature

probe).

A fast blinking LED indicates that the labeled function

has been tripped; an overpressure condition or motor

overload or high air temperature (HAT) trip.

A slow blinking LED indicates that the separator

differential pressure (DP) switch has been tripped.

A steady LED, along with a message blinking on the

display, indicates a service time-out. The controller is

programmed with recommended service intervals on the

fluid filter and the air filter. These filters should be

checked and serviced when indicated.

Basic Controls

1)

MENU

- scrolls through the set parameters as

indicated by the LED lamps to the left, in the

following order:

a) System pressure (default)

b) Discharge temperature

c) (Total) Running Hours - shows

run

followed by

the hours in alternating form.

d) Loaded Hours - shows

load

followed by the

hours in alternating form.

e) Separator Hours - shows

SEPA

followed by the

hours in alternating form.

f) *Air Filter Hours - shows

AIr.f

followed by the

hours in alternating form.

g) *Fluid Filter Hours - shows

Flu.f

followed by

the hours in alternating form.

h) Fluid service/sample hours - shows

FLu

followed by the hours in alternating form.

(Total/Loaded LED)

*These have no associated LED indicators.

Содержание QSB Series

Страница 2: ......

Страница 9: ...Section I General Quincy Compressor QSB T 5 MODEL IDENTIFICATION...

Страница 21: ...Quincy Compressor QSB T 17 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 27: ...Quincy Compressor QSB T 23 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 71: ...Quincy Compressor QSB T 67 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 72: ...Appendix A Dimensional Drawings 68 Quincy Compressor QSB T QSB 15 50 HP air cooled...

Страница 73: ...Appendix A Dimensional Drawings Quincy Compressor QSB T 69 QSB 15 50 HP water cooled...

Страница 74: ...Appendix A Dimensional Drawings 70 Quincy Compressor QSB T QST 15 50 HP air cooled 120 gallon tank...

Страница 75: ...Appendix A Dimensional Drawings Quincy Compressor QSB T 71 QST 15 50 HP water cooled 120 gallon tank...

Страница 76: ...Appendix A Dimensional Drawings 72 Quincy Compressor QSB T QST 15 50 HP air cooled 200 gallon tank...

Страница 77: ...Appendix A Dimensional Drawings Quincy Compressor QSB T 73 QST 15 50 HP water cooled 200 gallon tank...