Section IV - Operating Procedures

18

Quincy Compressor

®

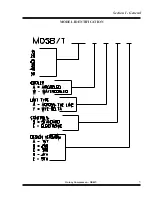

- QSB/T

™

• Prior to Starting

• Starting the Compressor

• Stopping the Compressor - Normal

Operation

• Stopping the Compressor - Emergency

• Electronic Control Operation (optional)

Prior to Starting

CAUTION!

Provisions should be made to have the instruction

manual readily available to the operator and

maintenance personnel. If, for any reason, any

parts of the manual become illegible or if the

manual is lost, have it replaced immediately. The

instruction manual should be read periodically

to refresh one’s memory. This may prevent a

serious accident.

Before starting the compressor, review Sections II and III

of this manual. Be certain that all installation

requirements have been met and that the purpose and use

of the controls are thoroughly understood. Before placing

the compressor into operation, do the following:

•

Remove all loose items and tools from around the

compressor.

•

Check fluid level in the air/fluid reservoir. See

Compressor Fluid Section.

•

Check the fan and fan mounting for tightness.

•

Manually rotate the compressor through enough

revolutions to be certain there are no mechanical

interferences.

•

Check all pressure connections for tightness.

•

Check to make sure all relief valves are in place.

•

Check to make sure all panels and guards are in place

and securely mounted.

•

Check fuses, circuit breakers and thermal overloads

for proper size.

•

Close the main power disconnect switch and jog the

starter switch button to check the rotational direction

of the compressor.

•

Check the fan rotation.

• Water-cooled models

- Check inlet and discharge

water piping for proper connections.

•

Check for proper belt tension.

(Reference V-belt

Drive Maintenance - Section VI.)

Starting the Compressor

•

Secure all enclosure panels on compressor.

•

Open the service valve to the plant air distribution

system.

•

Select the mode of operation and start the

compressor.

•

Watch for excessive vibration, unusual noises or air/

fluid leaks. If anything unusual develops, stop the

compressor immediately and correct the condition.

•

Control settings have been adjusted at the factory;

however, they should be checked during start-up and

readjusted, if necessary. Some applications may

require a slightly different setting than those provided

by the factory. Refer to the Service Adjustment

Section VIII. Never increase air pressure settings

beyond factory specifications.

•

Adjust the water temperature regulating valve to

maintain 180°F discharge air temperature (water-

cooled units only).

•

Observe compressor operation closely for the first

hour of operation and frequently for the next seven

hours. Stop and correct any noted problems.

•

Check for proper belt tension after 24 hours and

adjust if necessary.

(Reference V-belt Drive

Maintenance - Section VI.)

Содержание QSB Series

Страница 2: ......

Страница 9: ...Section I General Quincy Compressor QSB T 5 MODEL IDENTIFICATION...

Страница 21: ...Quincy Compressor QSB T 17 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 27: ...Quincy Compressor QSB T 23 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 71: ...Quincy Compressor QSB T 67 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 72: ...Appendix A Dimensional Drawings 68 Quincy Compressor QSB T QSB 15 50 HP air cooled...

Страница 73: ...Appendix A Dimensional Drawings Quincy Compressor QSB T 69 QSB 15 50 HP water cooled...

Страница 74: ...Appendix A Dimensional Drawings 70 Quincy Compressor QSB T QST 15 50 HP air cooled 120 gallon tank...

Страница 75: ...Appendix A Dimensional Drawings Quincy Compressor QSB T 71 QST 15 50 HP water cooled 120 gallon tank...

Страница 76: ...Appendix A Dimensional Drawings 72 Quincy Compressor QSB T QST 15 50 HP air cooled 200 gallon tank...

Страница 77: ...Appendix A Dimensional Drawings Quincy Compressor QSB T 73 QST 15 50 HP water cooled 200 gallon tank...