QR-25 Series

Quincy Compressor

52201-107, December 2012

18

3501 Wismann Lane, Quincy IL - 62305-3116

air tank is dependent upon an internal tank pressure of 20 to 30 PSIG (no

more than 30 PSIG). Higher internal tank pressures are dangerous and could

cause serious injury!

Oil and moisture residue must be drained from the air receiver

daily or after each use. Accumulations of oil residue in the receiver

can be ignited by embers of carbon created by the heat of compres-

sion, causing an explosion, damage to property and injury to per-

sonnel.

Do not open a manual tank drain valve on any air tank containing

more than 30 PSIG of air pressure!

Never attempt to relieve an air tank by removing a pipe plug or

any other system component!

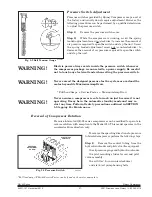

Manually Draining An Air Tank:

Step 1)

Disconnect & lockout the compressor from the power source (elec

tric models) or disconnect the spark plug wire from the spark plug

(gas engine models).

Step 2)

Tank(s) subjected to freezing temperatures may contain ice. Store

the compressor in a heated area before attempting to drain mois

ture from the tank(s). Reduce the air pressure in the tank to 30

PSIG by pulling the pressure relief valve ring (refer to Fig. 3-4,

Checking Pressure Relief Valves & Relieving System Pres-

sure).

Step 3)

Slowly open the drain valve and allow the moisture and air mixture

to drain from the tank.

Step 4)

Once the moisture has been completely drained, close the drain

valve.

Air Tank Inspection

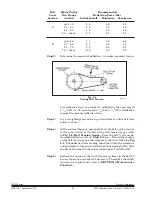

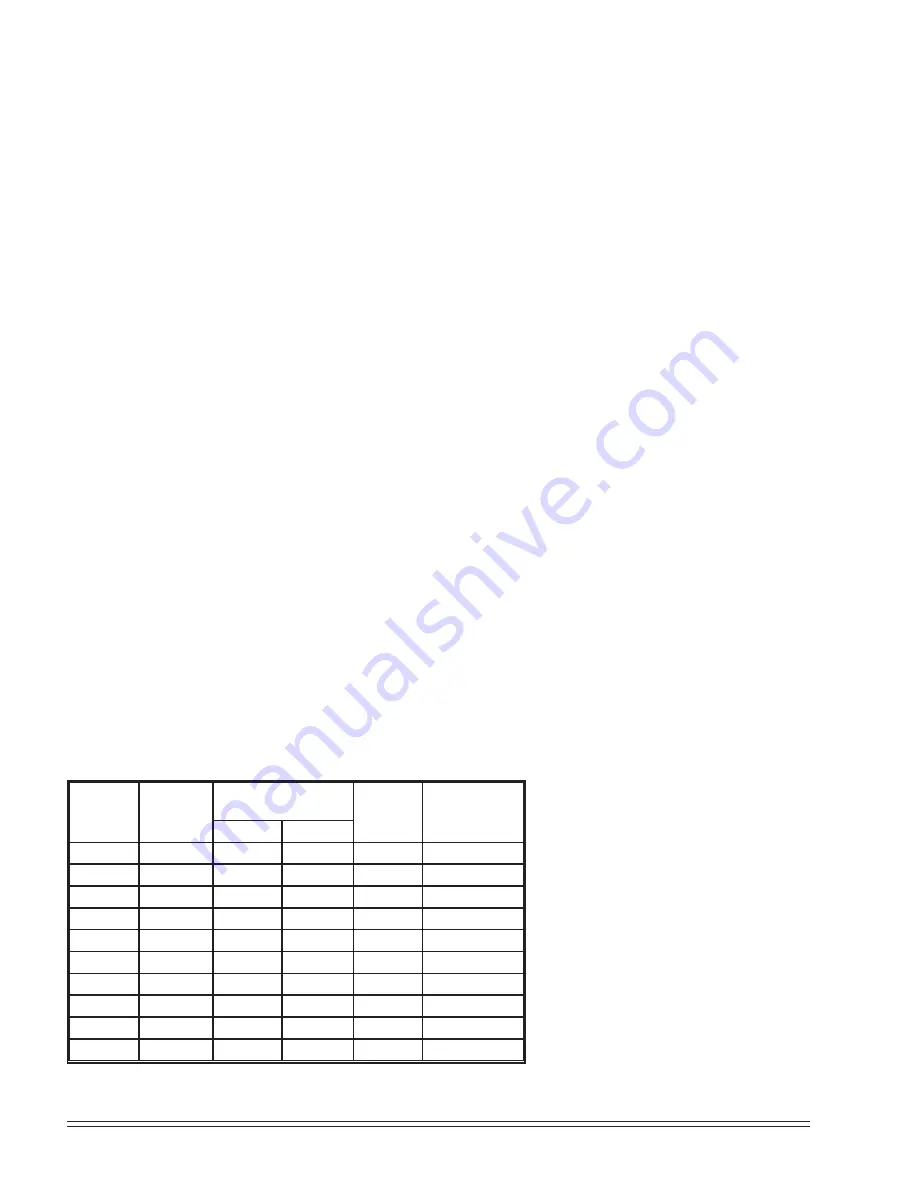

Quincy Compressor recommends that all

air tanks be inspected at scheduled inter

vals. Refer to Fig. 3-5 Recommended

Air Tank Inspection Intervals for

relative information. Measure tank wall

thickness at several locations, including

the lowest point where condensation can

accumulate.

Refer to federal, state or provincial,

or local codes for mandatory air tank

maintenance information.

WARNING !

WARNING !

WARNING !

Tank

Capacity

Horizontal

or

Vertical

Minimum Allowable

Wall Thickness

Visually

Inspect

Hydrostatically

Inspect

Head

Shell

30 Gal.

Horizontal

.094

.106

Yearly

10 Years

30 Gal.

Vertical

.109

.111

Yearly

10 Years

60 Gal.

Horizontal

.109

.135

Yearly

10 Years

60 Gal.

Vertical

.109

.111

Yearly

10 Years

80 Gal. Horizontal

.109

.135

Yearly

10 Years

80 Gal.

Vertical

.131

.133

Yearly

10 Years

120 Gal. Horizontal

.131

.162

Yearly

10 Years

120 Gal.

Vertical

.163

.199

Yearly

10 Years

200 Gal. Horizontal

.163

.199

Yearly

10 Years

240 Gal. Horizontal

.163

.199

Yearly

10 Years

Fig. 3-5 Recommended Air Tank Inspection Intervals

Содержание QR-25 210

Страница 42: ......