QR-25 Series

Quincy Compressor

52201-107, December 2012

11

3501 Wismann Lane, Quincy IL - 62305-3116

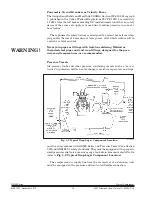

HORIZONTAL TANK UNITS

ANCHORED

VERTICAL TANK UNITS

ANCHORED

HORIZONTAL TANK UNITS

UNANCHORED

1/2” locknut

1/2” flat washer

tank foot

isolator backing plate

1/2” x 2” bolt

isolator

1/2” locknut

1/2” flat washer

tank foot

isolator backing plate

isolator

1/2” floor stud

(provided by customer)

1/2” floor stud

(provided by customer)

tank foot

1/2” locknut

1/2” flat washer

Fig. 3-1 Isolator Installation for

Unanchored or Anchored Receivers

Mounting

Proper mounting of Quincy compressor units is crucial to the safe operation

and longevity of the equipment. The installation requires a flat and level

concrete floor or pad

(for mobile units see

Mounting Mobile Units

).

Satis

factory results can usually be obtained by mounting horizontal tank units on

vibration isolators available from your local Quincy distributor.

All vertical

tank units must be anchored!

Quincy recommends that all vertical tank

units be mounted as indicated without

isolators. Refer to Fig. 3-1, Isolator Instal-

lation for Unanchored or Anchored

Receivers.

State or local codes may mandate that

the unit be bolted to the floor. In this case

the unit must be leveled and bolted making

absolutely certain the feet are not stressed

in any manner.

Leave the locknut loose!

Uneven feet drawn tightly to the concrete

pad will cause severe vibrations resulting

in cracked welds or fatigue failure. The

customer is responsible for pro viding a

suitable foundation & isolator mounting

where necessary.

Mounting Mobile Units

Units mounted to truck beds should be fas tened in such a way so as not to

create any stress to the air receiver tank. Truck beds, characteristically, have

a tendency to flex and could cause damage to the receiver tank if the tank is

fastened directly to the truck bed. It is the User’s responsibility to provide an

adequate means of fas tening the unit in these applica tions.

Do not operate this compressor more than 15° off level or move it

while it is operating.

System components

Efficiency and safety are the primary concerns when selecting compo nents

for compressed air systems. Products of inferior quality can not only hinder

performance of the unit, but could cause system failures that result in bodily

harm or even death. Select only top quality compo nents for your system. Call

your local Quincy distributor for quality parts and professional advice.

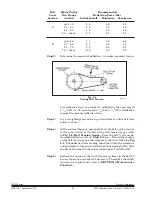

Drive Pulleys / Sheaves

Various pulley and sheave combinations are available to obtain the de sired air

pressure and delivery rate of your compressor. Consideration must be given

to these combinations to ensure that the motor is not over loaded by operating

above or below the designed speed range.

Whatever combination is employed, the drive pulleys & com pressor sheaves

must be properly aligned and drive belt tension set to specifica tions (refer to

SECTION 5,

Pulley / Sheave Alignment & Belt Tension

). Improper pul

ley/sheave alignment and belt ten sion can cause motor overloading, excessive

vibration, and prema ture belt and/or bearing failure.

CAUTION !

Содержание QR-25 210

Страница 42: ......