QR-25 Series

Quincy Compressor

52201-107, December 2012

24

3501 Wismann Lane, Quincy IL - 62305-3116

*High pressure rated compressors should maintain 22 to 25 PSIG of oil pressure.

•Drain receiver tank, drop legs and traps in air distribution system.

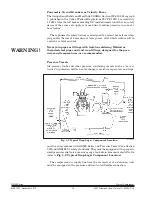

•Give compressor an overall visual inspection and be sure safety guards

are in place.

•Check for any unusual noise or vibration.

•Check lubricant pressure

(hot)

. Maintain 18 to 20 PSIG*

.

•Check for lubricant leaks.

•Check all pressurized components for rust, cracks or leaks. Immediately

discontinue use of the equipment and relieve all system pressure if

any of these problems are discovered. Do not use the equipment until

it has been inspected and repaired by a qualified mechanic.

Every 40 Hours (or Weekly)

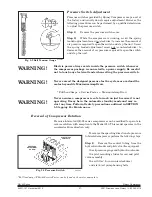

•Manually operate the pressure relief valves to be certain they are

working.

•Clean the cooling surfaces of the intercooler, aftercooler and compressor.

•Check the compressor for air leaks.

•Check the compressed air distribution system for leaks.

•Inspect lubricant for contamination & change if necessary.

•Clean or replace the air intake filter. Check more often under humid

or dirty conditions.

Every 160 Hours (or Monthly)

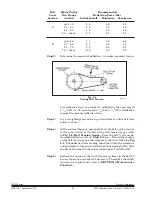

•Check belt tension

Every 500 Hours (or Every 3 Months)

•Change oil & filter (more frequently in harsher environments).

•Torque pulley clamp screws or jamnut.

Every 1000 Hours (or Every 6 Months)

•When QuinCip lubricant is used, lubricant change intervals may be

extended to every 1000 hours or every 6 months, whichever occurs

first (change more frequently in harsher conditions).

•Inspect compressor valves for leakage and/or carbon buildup. The

oil sump strainer screen inside the crankcase of pressure lubricated

models should be thoroughly cleaned with a safety solvent during every

oil change. If excessive sludge buildup exists inside the crankcase,

clean the inside of the crankcase as well as the screen. Never use a

flammable or toxic solvent for cleaning. Always use a safety

solvent and follow the directions provided.

Every 2000 Hours (or Every 12 Months)

•Inspect the pressure switch diaphragm and contacts. Inspect the

contact points in the motor / starter.

Lubrication

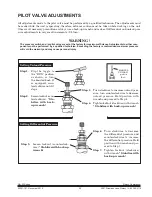

QR-25 Series compressors are normally shipped

with

lubricant in the

crankcase. Before starting your compressor, check the lubricant level in the

crankcase. The lubricant should register between the high and low marks on

the dipstick. Replace the break-in lubricant after 100 hours of opera-

tion or 1 month (whichever comes first) with Quin-Cip lubricant!

Содержание QR-25 210

Страница 42: ......