Residential Gas Hydronic Heating System

Residential Gas Hydronic Heating System

Residential Gas Hydronic Heating System

Residential Gas Hydronic Heating System

17

17

17

17

QVM 9

Series

Gas Piping Connections

Gas Piping Connections

Gas Piping Connections

Gas Piping Connections

■

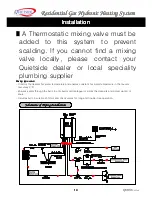

The heating water supply piping should be 3/4". An isolation (ball-type) valve should be installed before the

piping is connected to the units.

■

Black iron piping or 3/4" flexible connector (approved by the local authorities for gas) should be used for gas

piping.

■

Do not use Teflon tape for gas pipe connections.

■

Install a gas drip leg at the unit.

■

Gas piping should be kept at the required distance away from any electric lines and the main service

panel(check with local authorities).

Items

Items

Items

Items

Distance(inches)

Distance(inches)

Distance(inches)

Distance(inches)

1. Distance from electric lines

6"

2. Distance from electric heaters and electric panels

24"

3. Distance from flue pipes and outlets

12"

■

Install the ball valve(cut-off valve) before connecting the gas piping to the unit (Allow space for the lever

’

s

full movement, install valve as close to the unit as possible).

■

After the gas pipe has been completed, all connections must be checked with soapy water.

Note!

Note!

Note!

Note!

- Do not

test for gas leaks by pumping air-pressure into the line without first disconnecting the gas line to the unit.

Pressuring the unit will void the manufacturers warranty. Releasing this pressure into the unit will cause

immediate and severe damage to the gas valve and its internal pressure regulating device and could result in

property damage and/or personal injury.

Set DIP switch #1 to the ON position(priority fill). The pump will run continuously

and the low water level sensor will be automatically turned on/off for 1-minute

intervals. Ensure that all water valves to unit are open.

Twist open(approx. 1/2 turn) the manual air vent until a steady stream of water

is flowing and the spurting of air stops.

–

Open all other bleed valves on system.

Close the manual air vent (any remaining air will bleed out of the system by

means of the automatic air vent).

After the quick fill is complete, reset the #1 DIP switch to the OFF position.

If the heating flow sensor stays ON, stop the pump by resetting the #1 DIP

switch(switch ON, then back OFF again)

Remove strainer, check for debris, clean and refit.

Ensure that system pressure has been bled off using the pressure / relief valve

NOTE !

NOTE !

NOTE !

NOTE !

-

-

-

- While in the Quick Fill mode, the power indicator light, on the FR-5 thermostat will flash:

1-second ON and 1-second OFF.

Standard Gas Piping

Standard Gas Piping

Standard Gas Piping

Standard Gas Piping

Consult with your gas provider to determine the proper diameter of gas pipe. This will vary

Consult with your gas provider to determine the proper diameter of gas pipe. This will vary

Consult with your gas provider to determine the proper diameter of gas pipe. This will vary

Consult with your gas provider to determine the proper diameter of gas pipe. This will vary

due to input capacity, the number of elbows and length of pipe.

due to input capacity, the number of elbows and length of pipe.

due to input capacity, the number of elbows and length of pipe.

due to input capacity, the number of elbows and length of pipe.

Trial operation Quick-Fill

Trial operation Quick-Fill

Trial operation Quick-Fill

Trial operation Quick-Fill

STEP 1

STEP 1

STEP 1

STEP 1

STEP 2

STEP 2

STEP 2

STEP 2

STEP 3

STEP 3

STEP 3

STEP 3

STEP 4

STEP 4

STEP 4

STEP 4

STEP 5

STEP 5

STEP 5

STEP 5

STEP 6

STEP 6

STEP 6

STEP 6