Residential Gas Hydronic Heating System

Residential Gas Hydronic Heating System

Residential Gas Hydronic Heating System

Residential Gas Hydronic Heating System

QVM 9

Series

12

12

12

12

Installation

Installation

Installation

Installation

■

The flue should be properly installed as indicated on the

installation manual.

■

Dampers available in the market have high rate of

failure and disturb the normal operation of the boilers.

Never install any dampers.

■

Maximum length of the flue is 16 feet with upto three

90

°

Elbows being used. Flue

Ø

is 3

”

only.

See page 18 for details

See page 18 for details

See page 18 for details

See page 18 for details

■

Check if the gas indicated on

the rating plate is being used. If

not, change the nozzle by

consulting the service center or

dealers.

CONVERSION OF THIS APPLIANCE FROM NATURAL

GAS TO PROPANE CAN ONLY BE PERFORMED BY A

QUALIFIED TECHNICIAN.

■

The units must be firmly secured on the wall, which

can sufficiently hold the unit weight.

■

Exhaust vent pipe has a maximum length of 16 feet

with upto three 90

°

elbows. Vent pipe must be angled

2-3

°

toward the boiler to return condensate.

■

The units should be grounded to prevent electric

shock.

■

Do not apply torch heat within 12" of the bottom

connections of the unit.

■

Perform all solder connections at a safe distance from

the (brass) male connectors below the unit. Allow fittings

to cool, before attaching to unit. Use only approved

coupling unions with O-rings to attach field piping to

unit.

■

The

‘

heating

’

pipe should be 3/4" and of type-L copper,

or PEX. Never use aluminum, plastic, or galvanized steel

piping.

■

The pipe size used for

supply

supply

supply

supply heating water should be

the same size used for the

return

return

return

return heating water.

■

Use only copper piping with lead-free solder for the

domestic water side.

■

Since the expansion tank has already been installed in

the unit, no separate tank is required.

■

The size of the domestic hot water pipe should be 1/2"

diameter.

■

The length of piping should be as short as possible and

the piping should have minimal number of bends and

connections.

■

Use only ball type isolating valves. Do not use gate

valves.

■

Never leave the heating pipes disconnected while

operating the unit as a boiler. This will cause damage to

the heat exchanger and void the manufacturers

warranty.

■

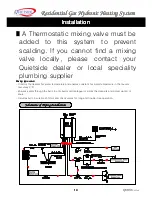

All piping should be insulated.

■

After making the piping connections, check for gas or

water leaks.

■

If the water supply pressure is 142 psi or higher, install the

reduction valve on the water supply piping.

■

If the water supply pressure is 4.3 psi or lower, install a

■

The piping materials used should

meet local codes and industry

standards.

■

Piping must be cleaned and flushed-

out before installation.

Check

Check

Check

Check the of Gas

the of Gas

the of Gas

the of Gas

Methods of Installation

Methods of Installation

Methods of Installation

Methods of Installation

Installation of Water Piping

Installation of Water Piping

Installation of Water Piping

Installation of Water Piping

Installation of the Flue

Installation of the Flue

Installation of the Flue

Installation of the Flue