D

T

p

A

R

R

T

Disassembly

The

followin

position

num

Assembly/di

Replacing

el

Operation

1

Disassem

2

Unscrew

3

Remove

diaphrag

4

Unscrew

5

Change

t

diaphrag

6

Take

out

pump

‐

ho

7

Change

t

socket

h

8

Change

t

9

Change

t

Replacing

sh

Operation

1

Disassem

2

Unscrew

3

Assembl

4

Unscrew

coupling

(sketch

b

5

Unscrew

while

ass

which

is

6

Assembl

Tightening

to

Pos.

‐

No.

2.11

2.8

2.12

5.2.2

Operation

1

Unscrew

2

Unscrew

3

Unscrew

4

Assemb

y/Assembly

Q

ng

tables

de

mbers

the

pa

isassembly

p

astomers

mble/assembl

w/tighten

up

t

the

diaphrag

gms

w/tighten

up

t

the

diaphragm

gm

‐

supports

t/assemble

th

ousing

the

outlet

‐

val

ead

cap

screw

the

inlet

‐

valve

the

o

‐

rings

ins

haft

‐

bearing

‐

mble/assembl

w/tighten

up

t

e/take

out

th

w/tighten

up

t

g,

while

assem

below)

w/tighten

up

t

sembling

of

fi

shown

in

the

e/take

out

th

orques

Too

Hex

Hex

Hex

Hex

w/tighten

up

t

w/tighten

up

t

w/tighten

up

t

le/take

out

th

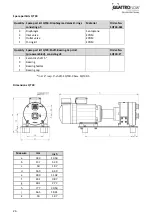

QT20

escribe

the

rts

can

be

id

pump

chamb

e

pump

cham

he

hexagon

so

m

‐

housing

‐

co

he

hexagon

so

ms

by

unscrew

e

valve

‐

plate

ve

by

unscrew

w

e

inside

the

va

side

the

pump

‐

cap

‐

unit

e

pump

cham

he

hexagon

so

e

whole

comp

he

hexagon

so

mbling

please

n

he

hexagon

so

ixingring

(Pos.

sketch

below

e

shaft

‐

bearin

ol

x

tip

screw

drive

x

tip

screw

drive

x

tip

screw

drive

x

tip

screw

drive

the

locking

scr

the

hexagon

s

the

hexagon

s

he

whole

com

assembly/di

dentified

in

th

ber

mber,

as

descri

ocket

head

ca

over,

clamp

‐

rin

ocket

head

ca

wing/tightenin

and

the

o

‐

rin

wing/tighten

u

alve

‐

plate

p

‐

housing

mber,

as

descri

ocket

head

ca

ponent

ocket

head

ca

note

the

lash

f

ocket

head

ca

.

1.1.3)

use

th

ng

‐

cap

‐

unit

er

(4mm)

er

(5mm)

er

(5mm)

er

(2,5mm)

rew

ocket

head

ca

ocket

head

ca

ponent

isassembly

o

he

exploded

ibed

above

ap

screw

ng

and

ap

screw

ng

up

the

gs

of/into

the

up

the

hexago

ibed

above

ap

screw

ap

screw

of

th

for

the

couplin

ap

screw

,

e

mounting

a

ap

screw

ap

screw

of

a

QT20

s

views.

Pos.

‐

No.

2.8

2.3,

2.4,

2.10

2.1.1,

2.5

e

2.2,

2.6.2

2.6.4.2,

2

on

2.6.3,

2.9

2.6.3,

2.2

2.6.4.2,

2

Pos.

‐

No

1.8

e

ng

5.2.2

id

1.6

1.1.1

– 1

Pos.

‐

No

1.5

2.11

2.12

standard

pu

2.6.1

5

2,

2.6.3,

2.6.4.3

9

2

2.6.4.3,

2.1

.

1.1.10

Tig

.

ump.

Via

the

Tool

Hex

tip

screw

Hex

tip

screw

Hex

tip

screw

needle

nose

Tool

Hex

tip

screw

Hex

tip

screw

(2.5mm)

Hex

tip

screw

(mounting

a

ghtening

torq

6

5

10

1.4

Tool

Hex

tip

screw

Hex

tip

screw

Hex

tip

screw

1

e

mentione

w

driver (5mm

w

driver (4mm

w

driver

(3mm

pliers

w

driver (5mm

w

driver

w

driver (4mm

aid)

que

[Nm]

w

driver

(5mm

w

driver

(5mm

w

driver

(5mm

9

d

m)

m)

m)

m)

m)

m)

m)

m)

Содержание QT 10

Страница 7: ...QT 30 0 psii 43 p psi 87 psi 7...

Страница 17: ...17 Pump chamber incl connections QT10 C Drive unit QT10 A...

Страница 20: ...20 Components QT20 Drive unit A ring drive B pump chamber C Ring drive QT20 B...

Страница 21: ...21 Pump chamber incl connections QT20 C Drive unit QT20 A...

Страница 24: ...24 Components QT30 Drive unit A ring drive B pump chamber C base plate D Ring drive QT30 B...

Страница 25: ...25 Pump chamber incl connections QT30 C Drive unit and base plate QT30 A D...