27

TROUBLE

SHOOTING

Operating

troubles

Cause/remedial

action

Pump

does

not

start

Pump

does

not

prime

Output

is

not

obtained

Pressure

head

is

not

obtained

Output

is

not

consis

‐

tent

Pump

oper

‐

ates

noisy

Pump

is

leaky

Motor

gets

too

warm

The

4

‐

piston

diaphragm

pumps

operate

very

reliable

and

error

‐

free,

if

they

will

be

operated

and

serviced

in

accordance

with

the

instruction

manual.

1

X

X

The

screws

of

the

pump

chamber

maybe

not

tightened

enough.

Fix

it!

2

X

Check

the

direction

of

flow

showed

by

the

arrow

on

the

pump,

in

case

of

wrong

way,

turn

the

pump

head.

3

X

X

X

Check

suction

pipeline

and

TC

‐

seals

for

tightness.

4

X

X

X

X

Check

suction

head

‐

increase

suction

line

cross

section.

5

X

X

X

Check

viscosity

of

liquid

pumped.

6

X

Check

power

supply

and

cables.

7

X

X

X

Avoid

air

inclusions

in

the

liquid

to

be

pumped.

8

X

X

Check

pressure

head

‐

open

valve

in

discharge

line

completely,

remove

obstruction

in

discharge

line.

9

X

X

The

diameters

of

the

pipes

in

suction

or

pressure

line

are

too

small.

10

X

Check

the

coupling

halves.

They

must

be

fixed

with

a

lash.

11

X

Check

longitudinal

play

of

coupling

rod

pins.

The

spider

might

be

worn.

12

X

X

X

Check

whether

foreign

bodies

in

pump.

13

X

X

Pump

stopped

by

the

thermal

circuit

breaker.

Allow

the

motor

to

cool

down

–

maybe

reduce

the

power

consumption.

14

X

X

Bearings

are

worn

or

defective

and

must

be

replaced.

15

X

The

valves

are

dry

(e.g.

not

in

use

for

a

long

time),

deformed

or

worn.

Change

valve

or

wet

the

pump.

16

X

The

diaphragm

is

burst

‐

replace.

17

X

X

X

X

O–rings

between

valve

plate

and

pump

housing

are

defective.

18

X

Align

coupling

accurately.

19

X

X

The

clamping

ring

screw

got

loose

–

fix

it.

20

X

Parameters

of

the

control

panel

are

wrong

–

check

basic

settings.

21

X

Pump

after

SIP

cooled

down

too

fast

‐

slow

cooling

with

room

temperature

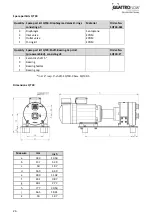

Содержание QT 10

Страница 7: ...QT 30 0 psii 43 p psi 87 psi 7...

Страница 17: ...17 Pump chamber incl connections QT10 C Drive unit QT10 A...

Страница 20: ...20 Components QT20 Drive unit A ring drive B pump chamber C Ring drive QT20 B...

Страница 21: ...21 Pump chamber incl connections QT20 C Drive unit QT20 A...

Страница 24: ...24 Components QT30 Drive unit A ring drive B pump chamber C base plate D Ring drive QT30 B...

Страница 25: ...25 Pump chamber incl connections QT30 C Drive unit and base plate QT30 A D...