Installation instructions

1 Ready to install

A : Installation Preparation

1 Choose flat on the ground in order to guarantee the machine level

2 Enough operation space

3 Avoid high temperature and high humidity environment

4 Check whether there is any damage on the power cord

B: Considerations

1 Electrical considerations

a:Use the voltmeter to check the power supply voltage is correct,connection

is reliable

b: Please confirm is safely grounded

c:Please confirm the hardware connection is firm and reliable

2 Air supply matters needing attention

a:Please make sure the external air trachea and the machine connection is

normal

b:Please make sure the vacuum mechanical and electrical source connected

with the machine to normal

3 Security considerations

a:Before moving to the machine, shut off the power, disconnect cables.

b:Handling personnel, pay attention to personal safety.

c:Before power on, confirm there is no foreign body in the machine

d:Before power on, manual review agencies operating normally, without

obstacles.

E: An emergency, press the red stop switch, system power is disconnected.

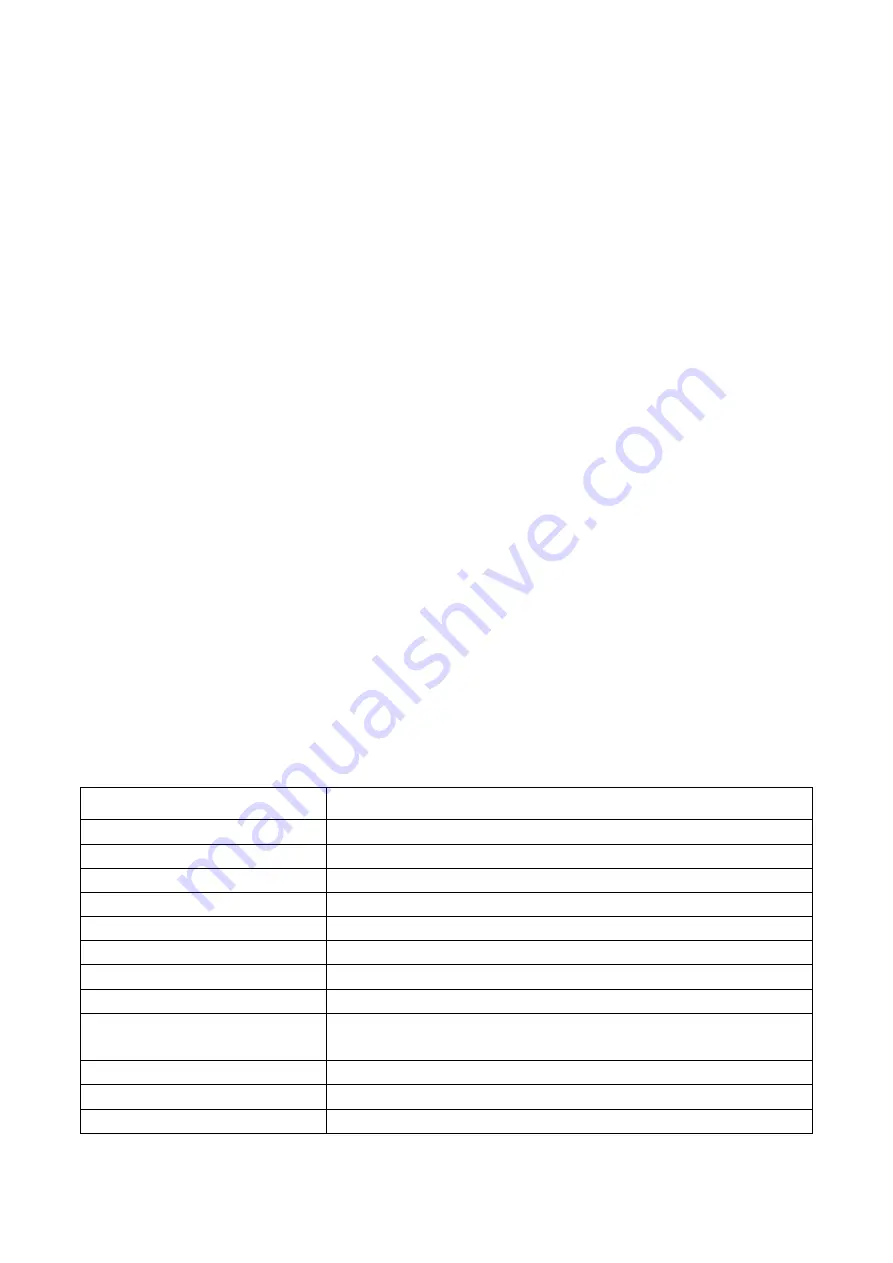

Technical Parameters

Item

Specification

Name

Multi-axis automatic placement machine

Model

MT-60

Placement head quantity

1

Speed

<6200CPH

Positioning accuracy

0.025mm

Feeders number

56

(

8mm=50,12mm=4,16mm=2

)

,

Applicable Components

0603-1206

,

diode, triode, capacitance, resistance, chip, etc

Feeders

8mm=50

,

12mm=4

,

16mm=2

Offline store the number of

files

20

Applicable PCB

300mm×400mm

Power supply

220V

,

50/60Hz

,

350W

Vacuum pump

0

~

30Kpa

(

Low vacuum

)

,

20L/min

Содержание MT-60

Страница 23: ......