6

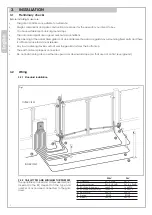

Fig. 9

Fig. 10

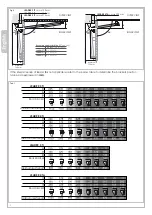

B

A

C

D

90°

B

A

D

90°

min.

30÷35 mm

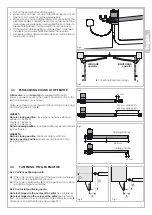

Fig. 11

Fig. 12

Fig. 13

T1

PR1

G1

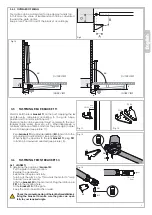

Fig. 14

PR1

G1

S3

2 cm

3.4.3 OUTWARD OPENING

Your gate can be automated for opening outwards too.

In this case the value of

A

dimension shall be calculated

towards the gate center.

See picture 9 and 10 and fit the bracket accordingly.

INNER VIEW

OUTER VIEW

INNER VIEW

OUTER VIEW

3.5 FASTENING REAR BRACKET T1

Weld or bolt the rear

bracket T1

on the post, applying the

A

and

B

quota calculated according to the gate hinge

position and the motor rotation point.

Chemical bolts can be used and must comply with the post

features (brick, wood, steel, etc. etc.). When fixing keep a

minimum distance of 30/35 mm from the post edge in order

to avoid damages (see picture 11).

- Rear

brackets T1

are provided

LH

and

RH

, to match to the

according LH and RH motor (see picture 12).

- When fixing the operator to the rear

bracket T1

, plug

PR1

rotation pin downward oriented (see picture 13).

3.6 FASTENING FRONT BRACKET S3

3.6.1 LEADER TI

To determine the position of

bracket S3

:

- Put the gate in closing position.

- Release the gearmotor.

- Extend the inox pipe arm fully.

- Turn back the arm 2 cms. This avoids the motor to “leap

forward” (see picture 14)

- Affix the

bracket S3

to the motor slot. Plug the rotation pin

PR1

into the locating hole.

- Fit the

bracket S3

on the gate.

- Keep the motor horizontal, fix or weld.

Check the manual opening of the leaf before definitively

fixing the bracket to make sure the gate can open

fully to your required angle.

T1

RH

T1

LH

Содержание LEADER 3

Страница 1: ...01_17 LEADER Gearmotor for swing gates INSTALLATION MANUAL...

Страница 2: ......