1

1. SAFETY INSTRUCTIONS

TWarning: Important safety instructions for people, READ CAREFULLY when you see this symbol:

This product must only be used for its intended purpose. Any other use is dangerous.

Follow all instructions as improper installation may result in in serious bodily injury.

Keep these warnings together with the installation and operation manuals that come with the gearmotor.

Always cut off the power supply before performing any type of intervention.

Always make sure the gearmotor is properly connected to the earth

Use and installation of the product must comply with Machinery Directive 2006/42/CE.

Verify that the system is EN 124445 and EN 12453 standard compliant.

Installation must be carried out by expert qualified personnel who knows the potential hazards associated

and in full compliance with current regulations.

Use of the product must be restricted to its intended use. Any other use is to be considered dangerous and therefore forbidden.

Do not allow children to play with the fixed command devices, or in the gate’s area of operation.

Keep any remote control devices (i.e. transmitters) away from children,

to prevent the gearmotor from being accidentally activat

Keep the gate and the gate opener regularly maintained. Use only Proteco’s original spares.

Users are strictly forbidden to carry out any changes on the gate operator.

Proteco Cancelli Automatici Srl is not liable for any damage resulting from improper, wrongful or unreasonable use.

CE

COMPLIANCE DECLARATION

Manufacturer:

PROTECO S.r.l.

Address

:

Via Neive, 77 – 12050 Castagnito (CN) – ITALIA

declares that

IThe product type:

LEADER electromechanical gear motor for swing gates

Models:

LEADER 3 TI, LEADER 4 TI, LEADER 5 TI, LEADER 24 3 TI, LEADER 24 4 TI, LEADER 24 5 TI

LEADER 3 TA, LEADER 24 4 TA

Is built to be integrated into a machine or to be assembled with other machinery to crate a machine under provisions of 2006/42/EC Machinery

Directive, with reference in particular to the following requirements: 1.1.2 1.1.3 1.1.5 1.2.1 1.2.2 1.2.3 1.2.6 1.3.2 1.3.4 1.3.9 1.4.1

1.4.2.1 1.5.1 1.5.4 1.5.6 1.5.8 1.5.13 1.6.1 1.6.4 1.7.1 1.7.3 1.7.4

ÈIt complies with the essential requirements of EEC Directives:

2004/108/CE

(electromagnetic compatibility)

1999/5/CE

(R&TTE)

2011/65/CE

(directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment)

It complies with the essential requirements of EEC Directives:

EN 12453

Industrial, commercial and garage doors and gates. Safety in use of power operated doors. Requirements

EN12445

Industrial, commercial and garage doors and gates. Safety in use of power operated doors. Test methods.

EN 60335-1

Safety of household and similar electrical appliances - Part I: General requirements

EN 60335-2-103

Household and similar electrical appliances - Part 2-103: Particular requirements for drives for gates, doors and windows.

The manufacturer also declares that the start-up of the machinery is not permitted unless the machine, in which the product is incorporated or of

which is becoming a component, has been identified and declared as conformed to 2006/42/EC Machinery Directive.

Castagnito, 3 October 2016

Marco Gallo

CEO

2. DESCRIPTION AND INTENDED USE

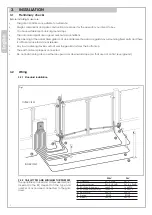

The LEADER operator range is designed to automate swing gates for residential use.

The use of this product for purposes other than those described above and installation executed in a manner other than

as instructed in this technical manual are prohibited.

All LEADER systems are irreversible, therefore no electric-lock is needed.

In case of power cut the gate operator can be easily released by manual operation.

The 24V LEADER systems can be connected to a back-up battery to grant a full operation cycle in case of power cut.

Содержание LEADER 3

Страница 1: ...01_17 LEADER Gearmotor for swing gates INSTALLATION MANUAL...

Страница 2: ......