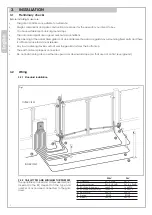

Fig. 1

3

A

D

E

B

C

F

C

A

C

C

INNER VIEW

OUTER VIEW

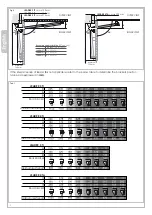

3. INSTALLATION

3.1

Preliminary checks

Before installing make sure:

•

The gate conditions are suitable to automate.

•

Weight, dimensions and gate construction are proper for the operator you intend to buy.

•

You have suitable mechanical ground stops.

•

The automated parts are in good mechanical conditions.

•

The opening of the automated gate is not an entrapment hazard as regards any surrounding fixed parts and there

is sufficient space for manual release.

•

Any lawn watering devices will not wet the gearmotor from the bottom up.

•

The earth cable is properly connected.

•

Do not install onto gates on either an upward or downward slope (i.e. that are not on flat, level ground).

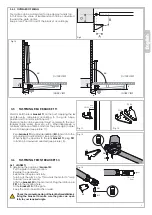

3.2 Wiring

3.2.1 Standard installation

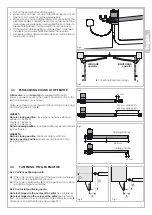

3.2.2 CABLE TYPES AND MINIMUM THICKNESSES

The quantities of tubes and cables needed (not

included in the kit) depend on the type and

number of accessories connected to the gate

area.

A

operator

3x1,5 Earth

B

Control panel

2x1,5 + Earth

C

Photocell receiver

rx 4x0,75

C¹

Photocell transmitter

tx 2x0,75

D

Key switch 2x0,75

E

Aerial

RG58

F

Blinker 2x0,75

230V

2x1,5

2x1,5 + Earth

rx 4x0,75

tx 2x0,75

2x0,75

RG58

2x0,75

24V

Содержание LEADER 3

Страница 1: ...01_17 LEADER Gearmotor for swing gates INSTALLATION MANUAL...

Страница 2: ......