7

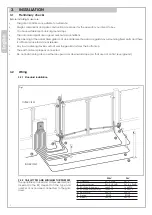

Fig. 15

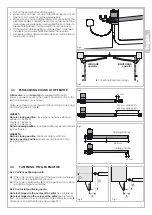

Fig. 17

45 mm

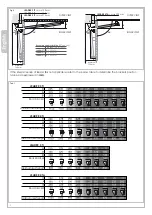

Fig. 16

S4

M12

3.6.2 LEADER TA

To determine the position of

bracket S4

:

- Put the gate in closing position

- Release the gearmotor

- Slide the front drive pin to the closing limit-switch point

(keep a distance of 45 mm between the pin and the

pipe end terminal (see picture 15).

- Fix the

bracket S4

to the drive pin. See picture 16.

- Fit the

bracket S4

onto the gate and keep the motor

horizontal. Fix or weld.

Check the manual opening of the leaf before definitively

fixing the bracket to make sure the gate can open

fully to your required anglee.

4. RELEASING THE GEARMOTOR

LH OPERATOR

- Insert the key and turn 90° clockwise (picture 17).

- Pull the release handle outwards to unlock the motor.

- Turn the key 90° clockwise to keep the handle locked.

- Now you can proceed to manual operation.

- To return to automatic operation invert the procedure.

RH OPERATOR

- Insert the key and turn 90° counterclockwise (picture 17).

- Pull the release handle outwards to unlock the motor.

- Turn the key 90° counterclockwise to keep the handle

locked.

- Now you can proceed to manual operation.

- To return to automatic operation invert the procedure.

The gate can be locked in any position after the first

start command the system will return to its default

settings.

5. MAINTENANCE

Functional checks must be performed once every 6

months, including: checking the state of lubrication and

tightness of the anchoring screws on the operator as well

as the good operation of all safety devices.

6. DISMANTLING AND DISPOSAL

DO NOT DISPOSE OF IN NATURE!

Some components may contain hazardous waste.

They must, thus, be removed and turned into licensed firms

for their disposal.

Before acting always check the local laws on the matter.

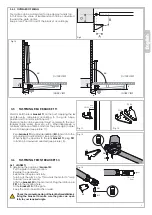

INNER VIEW

OUTER VIEW

LH

RH

Содержание LEADER 3

Страница 1: ...01_17 LEADER Gearmotor for swing gates INSTALLATION MANUAL...

Страница 2: ......