PD8-6262 Explosion-Proof Dual Analog Input Flow Rate/Totalizer

Instruction Manual

64

Troubleshooting

The rugged design and the user-friendly interface of

the totalizer should make it unusual for the installer or

operator to refer to this section of the manual.

However, due to the many features and functions of

the totalizer

, it’s possible that the setup of the totalizer

does not agree with what an operator expects to see.

If the totalizer is not working as expected, refer to the

Diagnostics

menu and recommendations below.

Diagnostics Menu (

diag

)

The

Diagnostics

menu is located in the

Advanced

Features

menu. To access the

Diagnostics

menu, see

on page

This menu allows the user to test the functionality of

all the totalizer LEDs, check the totalizer

’s software

and version information, and erase the MeterView Pro

software installation files from the totalizer. Press the

Enter

button to view the settings and the Menu button

to exit at any time.

For a description of the diagnostic messages,

see

Testing the Display LEDs

To test all LEDs on the display:

1. Go to the

Diagnostics

menu (

diAG

) and

press Enter button.

2. Press Up arrow button and scroll to

LED Test

menu (

led t

)

3. Press the Enter button to activate the LED

Test. The totalizer will cycle through all

digits, decimal points, and relay indicators to

enable the operator to check that all LEDs

are functioning properly.

4. Press the Enter button again to access the

Information

menu (

info

) or press the Menu

button to return to Run Mode.

Determining Software Version

To determine the software version of a totalizer:

1. Go to the

Diagnostics

menu (

diAG

) and

press Enter button.

2. Press Up arrow button and scroll to

Information menu (

Info

).

3. Press Enter to access the software number

(

SFT

) and version (

UER

) information. Write

down the information as it is displayed.

Continue pressing Enter until all the

information is displayed.

4. The totalizer returns to Run Mode after

displaying all the settings.

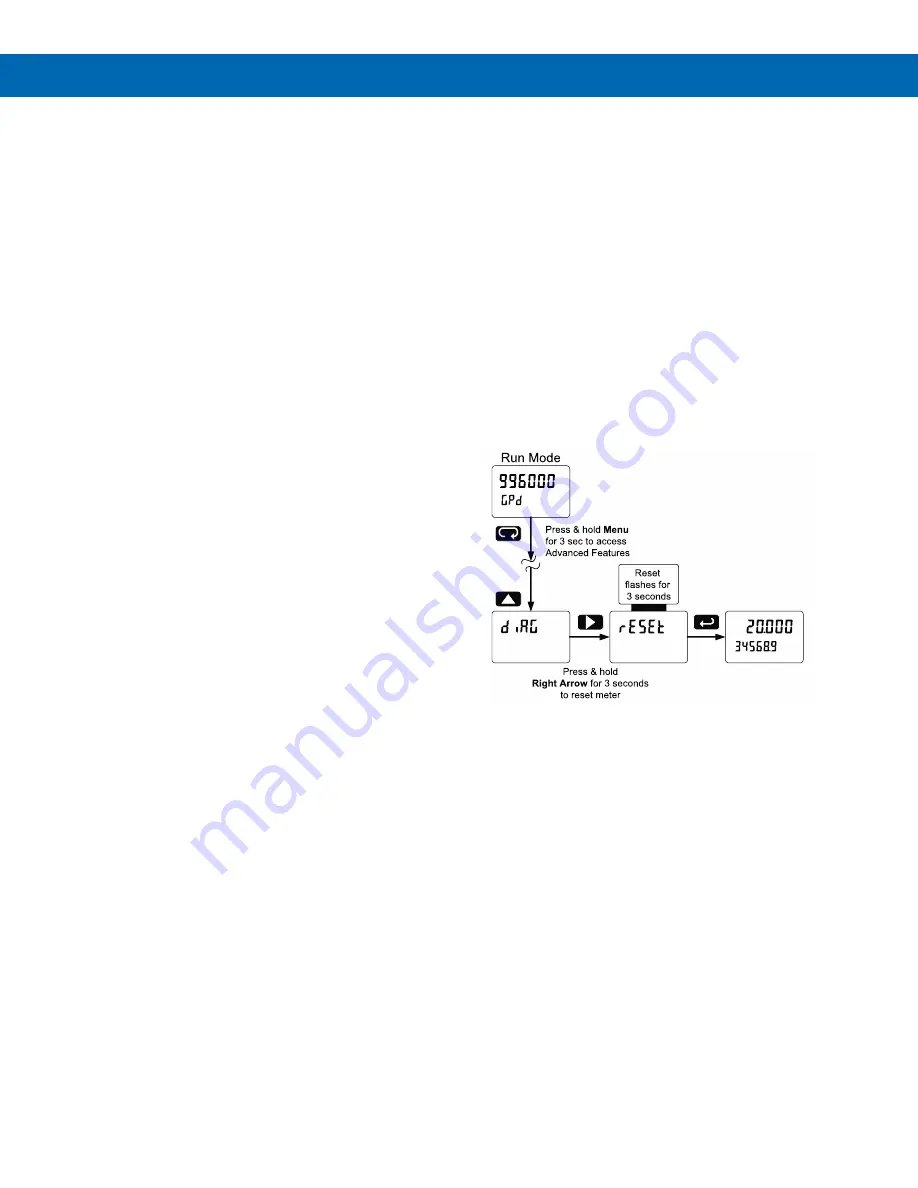

Reset Totalizer to Factory

Defaults

When the parameters have been changed in a way

that is difficult to determine what’s happening, it might

be better to start the setup process from the factory

defaults.

Instructions to load factory defaults:

1. Enter the

Advanced

Features

menu. See

2. Press Up arrow to go to

Diagnostics

menu

3. Press and hold Right arrow for three seconds,

press

Enter when display flashes

reset

.

Note:

If Enter is not pressed within three seconds, the

display returns to Run Mode.

4. The totalizer goes through an initialization

sequence (similar as on power-up), and loads the

factory default settings.