PMAC Air Compressor

Powerex

•

100 Mundy Memorial Drive

•

Mt. Juliet, TN 37122

•

USA

P 1.888.769.7979

•

F 513.367.3125

•

www.powerexinc.com

IN598601AV

•

01/2020

Page 9 of 12

Lock out and tag out electric power. Vent all air

pressure from the system and lock out and tag.

DO NOT LOOSEN THE SET SCREW THAT SECURES

THE DRIVE HUB TO THE MOTOR SHAFT.

Pump replacement is not feasible for technical

reasons. If a pump experiences catastrophic failure

or reaches the end of its useful life replace the compelete compressor

assembly.

Motor Replacement

1.

Remove the electric connections from the motor.

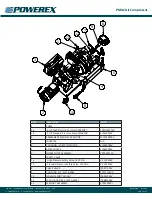

2. Remove coupling guard. Loosen the screws that secure the

coupling rubber element radially to the drive hubs.

3.

Loosen the hex head screws that hold motor adapter plate 1 to

motor adapter plate 2 (see image below). Support the body of

the motor so it can be pulled straight back. The drive coupling

hub will come free with the motor.

4.

Remove motor adapter plate 1 from the motor by removing

the 4 hex head screws that secure the motor to the adapter

plate.

5.

If the motor is being replaced, measure the position of the

motor slide drive hub relative to the existing motor shaft.

Loosen the setscrew and place the hub on the new motor and

position the new hub in the same location on the new motor.

Make sure the key is in place. Tighten the set screw to 7.5 ft-lbs

with Blue 242 Loctite.

6.

Installation is the reverse of removal. Be sure the key is in place

on the motor shaft and that the 4 alignment pins are in place

in the adapter plates.

7. Install and tighten the screws to secure the rubber element to

the motor drive hub.

8. Replace the coupling guard.

9.

Reconnect the electric power and verify proper rotation before

running the compressor more than a few seconds.

DO NOT LOOSEN THE HEXHEAD SCREW THAT

SECURES THE ADAPTING PLATE TO THE FACEPLATE.

Do not lose the 4 alignment pins installed in the

two motor adapter plates. These pins are required

to maintain alignment between the motor and the pump.