PMAC Air Compressor

Powerex

•

100 Mundy Memorial Drive

•

Mt. Juliet, TN 37122

•

USA

P 1.888.769.7979

•

F 513.367.3125

•

www.powerexinc.com

IN598601AV

•

01/2020

Page 2 of 12

This compressor/pump is NOT equipped and should NOT be

used “as is” to supply breathing quality air. For any application

of air for human consumption, you must fit the air compressor/

pump with suitable in-line safety and alarm equipment. This

additional equipment is necessary to properly filter and purify

the air to meet minimal specifications for Grade D breathing as

described in Compressed Gas Association Commodity Specifi

-

cation G 7.1 - 1966, OSHA 29 CFR 1910. 134, ANSI and/or Cana

-

dian Standards Associations (CSA).

DISCLAIMER OF WARRANTIES IN THE EVENT THE COMPRES

-

SOR IS USED FOR THE PURPOSE OF BREATHING AIR APPLICA

-

TION AND PROPER IN-LINE SAFETY AND ALARM EQUIPMENT

IS NOT SIMULTANEOUSLY USED, EXISTING WARRANTIES ARE

VOIDED, AND POWEREX DISCLAIMS ANY LIABILITY WHATSO

-

EVER FOR ANY LOSS, PERSONAL INJURY OR DAMAGE.

Breathable Air Warning

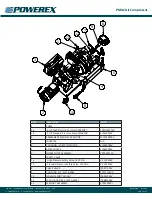

Components

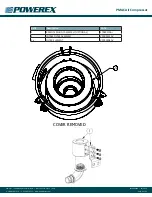

Oil-less Scroll Compressor Pumps

The Powerex scroll compressor offers a dynamically balanced air

end which insures vibration-free operation. The rotary design permits

a continuous 100% duty cycle. No oil separation, oil filtration, or inlet

valves are required on the Powerex Scroll unit.

Dry Type Inlet Filter

The 2µ filter provides protection for the precision components

within the compressor. This filter must be serviced at regular

intervals to maintain compressor performance. See page 4 for the

recommended maintenance schedule.

Isolation Mounts

The basic unit is supplied with isolation mounts. The installer may

substitute these mounts for a set of their own choosing. However, it is

recommended that Powerex review these alternate isolation mounts

that will be used in place of the supplied mounts.

Permanent Magnet AC Motor

The permanent magnet motor is very compact and is more efficient

compared with traditional induction motors.

Inverter

The inverter accepts 500 to 750 Volts DC which and changes it into

3 Phase 350 Volt AC to power the electric motor. This inverter also

provides data outputs which may interface with other systems via

analog and digital signals.

Default outputs:

Analog:

Power Consumption

0 to 10 V or 0 to 20 mA

Fault Signal: Normally Closed

24V

Fieldbus:

MODBus

Installation

Unpacking & Receiving the Unit

Immediately upon receipt of the compressor system, the unit

should be inspected for any damage which may have occurred in

shipment. Any shipping damage must be immediately filed with the

freight carrier. Repair or replace damaged items before use.

The compressor nameplate should be checked to see if the unit is

the correct model and voltage as ordered.

Do not operate unit if damaged during shipping,

handling or use. Damage may result in bursting

and cause injury or property damage.

Application

When the scroll compressor is to be used in applications other

than the compressing of atmospheric air, please contact a Powerex

representative for engineering and warranty information at 1-888-

769-7979.

Installation Site

1. The scroll compressor must be located in an environment

compliant with the compressor's intended use. If being

installed in an alternate location, please obtain prior approval

for change of location from Powerex.

2.

The area should be free of excessive dust, toxic or flammable

gases, moisture, water and direct sunlight.

3. Ambient temperatures of –35°F to +104°F are allowed. The

upper range of +104°F has a maximum on time of 4 minutes.

This is to ensure proper operation and prevent overheating.

4. Ambient Relative Humidity below 96% is allowed. Condensation

is not permitted.

5.

Clearance must allow for safe, effective inspection and

maintenance.

6.

Systems supplied without an aftercooler require an approved

check valve and safety valve to be installed downstream of the

compressor’s exhaust.

7. Air receiver(s) or alternate drive devices may be used to ensure

that the motor manufacturer’s recommended number of starts

and stops are not exceeded. Please refer to manufacturer for

details.

NOTE:

Contact Powerex for evaluation of ambient conditions

beyond the parameters above for special reduced duty cycle and

product life requirements.

Ventilation

1.

If the scroll compressor system is located in an enclosed area,

an exhaust fan or other means with access to outside air and

make up air must be installed.

2. Never restrict the cooling fan exhaust air.

3.

Never locate the compressor where hot exhaust air from other

heat generating units may increase the compressor’s operating

temperature.