10

Service Due Indication

“Service Due” indicates the dryer is due for routine

maintenance. Please read the maintenance section or

contact your Pneumatech dealer. In SERVICE DUE

mode, several functions relating to the accumulated run

time can be accessed. The accumulated run time can be

viewed, and the service due threshold (total

accumulated run time before SERVICE DUE indicator

lights) can be viewed and tested.

CAUTION

Drains will not operate normally in Service Due

mode. Drains will not receive power in Service Due

mode unless the DRAIN TEST key is held down.

Never operate the unit in Service Due mode for an

extended period of time.

To enter the SERVICE DUE mode (and view the

accumulated run time) press SELECT, UP (

↑

) and

DOWN (

↓

) keys simultaneously. The display will show

the accumulated run time in tens of hours. If the display

reads 50, for example, the accumulated run time is 500

hours.

1. To display the service due threshold, hit the DOWN

(

↓

) arrow key. The service due indicator will light up.

2. To test the service due timer function, push the

SELECT and UP (

↑

) keys simultaneously. The

accumulated run time will temporarily be set to a

value that is 60 seconds less than the service due

threshold setting. If the service due timer is

functioning properly, the SERVICE DUE indicator

will flash after the 60 seconds has elapsed. After a

few seconds, SERVICE DUE mode will return to

normal operation. The indicator will stop flashing and

the accumulated run time will return to its previous

value.

3. To reset the accumulated run time to zero, hold the

SELECT key for 5 seconds. To exit SERVICE DUE

mode, press the UP (

↑

) and DOWN (

↓

) keys

simultaneously. This can not be done while a service

due timer test is in progress.

SHUTDOWN PROCEDURE

1. Open the bypass valve to allow process flow to

continue downstream. Then close the outlet isolation

valve on the dryer bypass piping.

2. Close the inlet isolation valve on the dryer bypass

piping. At this time the dryer is isolated and can be

depressurized, ready for servicing.

3. Turn the power switch to the OFF position.

NOTE:

The alarm indication light (red) signifies the

refrigerant compressor is not running. The reasons can

be:

• Low suction pressure

• High discharge pressure

• Electrical problems

• Loss of refrigerant

• Dirty condenser

• Leaking evaporator, etc.

Refer to Troubleshooting Guide,

Page 16

, for problem

analysis and remedy. Call the factory if further

assistance is required.

CAUTION

Contact factory before authorizing any warranty

refrigeration service on the air dryer. Identify the

dryer by model and serial numbers when calling

factory.

OPERATING CONDITIONS

Entering Air Temperature

Units are designed for entering air temperature of 100°F

(38°C). If the temperature of entering air is to be greater

than 100°F (38°C), the factory should be consulted to

determine the maximum possible air flow through the

unit.

CAUTION

The increased heat content or higher temperature air

requires the dryer to be oversized to prevent

overloading of the refrigerant compressor.

Entering Air Pressure

Standard units are designed for operating air pressure

100 PSIG (150 PSIG MAX.). Operating below 100 PSIG

will reduce system capacity.

Ambient Air Temperature

The allowable ambient temperature range is 40°F to

110°F (4°C to 43°C). As temperatures approach freezing

conditions, frost or icing may develop in the unit. At

temperatures above 100°F (38°C), refrigeration capacity

will decrease, therefore affecting dew point.

Содержание AD Series

Страница 1: ...Noncycling Refrigerated Air Dryers AD 750 to 4000 Series Owner s Manual 9829 2103 73 August 2009 ...

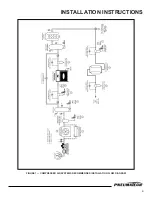

Страница 5: ...INSTALLATION INSTRUCTIONS 4 FIGURE 1 COMPRESSED AIR SYSTEMS RECOMMENDED INSTALLATION FLOW DIAGRAM ...

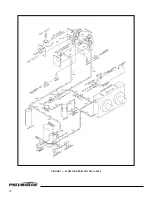

Страница 15: ...14 FIGURE 6 FLOW DIAGRAM AD 750 to 1000 ...

Страница 16: ...15 FIGURE 7 FLOW DIAGRAM AD 1200 to 2000 ...

Страница 17: ...FIGURE 8 FLOW DIAGRAM AD 2500 to 4000 16 ...

Страница 22: ...21 ...

Страница 23: ...22 ...

Страница 24: ...Pneumatech 4909 70th Avenue Kenosha WI 53144 Phone 262 658 4300 Fax 262 658 1945 www pneumatech com ...