7

START-UP AND OPERATION

The non-cycling design of the refrigerated dryer assures

proper dew point control at all load conditions. The

refrigerant compressor runs continuously when the dryer

is “ON”. All dryers are installed with fan cycling switches.

These fans will cycle with respect to the load changes,

ambient temperature fluctuations, and the cleanliness of

the condenser. Standard units are designed to operate

under the following conditions:

DESIGN CONDITIONS

1.

Inlet Air Temperature:

100°F (38°C) design 120°F (49°C)maximum

2.

Inlet Air Pressure:

100 PSIG design 150 PSIG maximum

3.

Ambient Air Temperature:

55°F (13°C) minimum 100°F (38°C) maximum

4.

Cooling Water Temperature:

90°F (32°C) maximum

5.

Cooling Water Pressure:

35 PSIG minimum 100 PSIG maximum

At temperatures above the 100°F (38°C) design,

refrigeration capacity will decrease. Operating air

pressures below the 100 PSIG design will reduce

system capacity.

START-UP PROCEDURE

1. If the suction pressure gauge reads zero, refrigerant

loss has occurred. Call the factory or distributor for

service.

CAUTION

CRANKCASE HEATER

Air dryers with three-phase power supply are

equipped with a compressor crankcase heater. This

heater must be energized by closing the disconnect

switch a minimum of 6 to 10 hours before start-up.

Power to the air dryer can be left on to energize the

crankcase heater for off-cycle, during evening or

weekend shutdowns (except scroll compressors).

CAUTION

STARTING THE DRYER WITHOUT ENERGIZING THE

CRANKCASE HEATER WILL CAUSE PREMATURE

FAILURE OF THE REFRIGERANT COMPRESSOR.

Failure to comply with procedure of energizing

crankcase heater before start-up may void warranty.

2. Check the temperature on the crankcase of the

compressor to make sure the crankcase heater is

working before starting the dryer.

3. For water-cooled Air Dryers (ADW) make sure the

water supply (Minimum Pressure 35 PSIG) is

available at the condenser inlet. The water

regulating valve will modulate and control the water

flow with respect to the dryer load conditions. The

water-cooled condenser drain plug (located inside

enclosure) must be installed.

4. For open frame design units [Models AD(W)-1500 &

larger], the following valves

must be open

prior to

start-up. All valves are tagged with specific

instructions.

a. Compressor isolation valves (suction &

discharge service valves).

b. Receiver valve(s) (air-cooled models only).

c. Condenser outlet liquid line valve (water-cooled

models only).

d. Hot gas line valve – Models AD(W)-2500 &

larger. Located on the hot gas line before the Hot

Gas Bypass Valve.

e. Liquid line valve on water-cooled condenser

outlet (water-cooled models only).

5. Turn the power ON/OFF switch to the ON position.

6. The suction pressure will gradually come down to

the blue or green range depending on the type of

refrigerant used in the air dryer. Check the

refrigerant suction pressure gauge reading. If the

suction pressure is above or below the suggested

color range, a hot gas bypass valve adjustment is

required. (Refer to the Hot Gas Bypass Valve

section of this manual.) For proper operating range

and control settings see listing below.

Содержание AD Series

Страница 1: ...Noncycling Refrigerated Air Dryers AD 750 to 4000 Series Owner s Manual 9829 2103 73 August 2009 ...

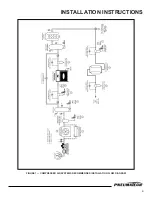

Страница 5: ...INSTALLATION INSTRUCTIONS 4 FIGURE 1 COMPRESSED AIR SYSTEMS RECOMMENDED INSTALLATION FLOW DIAGRAM ...

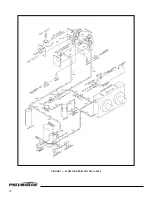

Страница 15: ...14 FIGURE 6 FLOW DIAGRAM AD 750 to 1000 ...

Страница 16: ...15 FIGURE 7 FLOW DIAGRAM AD 1200 to 2000 ...

Страница 17: ...FIGURE 8 FLOW DIAGRAM AD 2500 to 4000 16 ...

Страница 22: ...21 ...

Страница 23: ...22 ...

Страница 24: ...Pneumatech 4909 70th Avenue Kenosha WI 53144 Phone 262 658 4300 Fax 262 658 1945 www pneumatech com ...