MAINTENANCE

AIR DRYER MAINTENANCE

The dryer is factory tested before shipping. All controls

are calibrated for automatic operation. If the dryer is

installed in clean surroundings, within the temperature

limits of the specified ambient, the dryer will run trouble-

free for a very long time. Routine maintenance

procedures recommended are the following:

1. Checking the fan motor(s) for proper operation to

maintain the cooling air to be drawn through the

condenser and blown over the refrigerant

compressor. If the dryer is equipped with condenser

ambient filters, check, clean or replace as needed to

maintain the proper air flow through the condenser.

Dirty ambient filters will reduce the air flow through

the condenser, and trip the compressor “off” at the

overload control.

2. For dryers without ambient filters, clean the

condenser periodically to maintain the proper heat

transfer on the condenser coil. Dirty condenser will

raise the head pressure of the refrigeration system

and trip the compressor “off” at the overload control.

Running the compressor on high head pressures

may cause premature failures. Check the ambient

temperature limits to be maintained at the

installation.

3. Check and clean water-cooled condensers for dirt,

scale and sludge buildup every year or as needed.

Cooling tower water condensers may need cleaning

more often if the water is not properly treated.

4. Check the suction pressure gauge. Reading should

be within the specified range after a few minutes of

start-up. Suction pressure below the range will

cause freeze-up inside the air system, increasing the

pressure drop across the air dryer. Suction pressure

above the range will reduce the refrigeration cooling

capacity.

5. Check the pressure drop across the air dryer at full

capacity flow. If it is higher than specified value

(normally 5 PSI or less), consult factory. If pressure

drop increases over years of operation, it may be

due to particulate buildup from air compressor

intake. In that event, back-flush the dryer with any

MILD DETERGENT

. See Figure 2.

To back-flush, disconnect air dryer, plug the drain line

and fill the air system with the detergent water solution.

Hold it for 4-6 hours. Circulate the detergent from air

outlet to air inlet with a pump. Flush the system with

warm water. If pressure-drop still exists, contact factory.

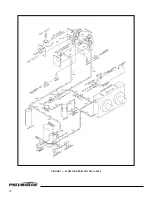

FIGURE 2 — BACK FLUSH FLOW DIAGRAM

AUTOMATIC DRAINS

The recommended settings for the drain time are

determined by the moisture load. The cycle time should

be adjusted to approximately 3 to 4 minutes. The drain

time should be set so the drain expels all of the liquid

and then a short burst of air.

Periodically check the automatic drains for proper

drainage. If the drains are not functioning, the

condensed moisture will be re-entrained downstream of

the air dryer. Float operated automatic drains need

periodic cleaning with soap and water to remove solids

from the valve seat. If the valve is stuck open, clean with

soap and water and then use compressed air to clean

the valve seat. Electronic solenoid operated drains may

be manually tested periodically for proper operation.

11

Содержание AD Series

Страница 1: ...Noncycling Refrigerated Air Dryers AD 750 to 4000 Series Owner s Manual 9829 2103 73 August 2009 ...

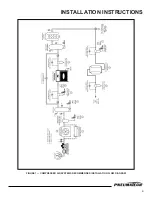

Страница 5: ...INSTALLATION INSTRUCTIONS 4 FIGURE 1 COMPRESSED AIR SYSTEMS RECOMMENDED INSTALLATION FLOW DIAGRAM ...

Страница 15: ...14 FIGURE 6 FLOW DIAGRAM AD 750 to 1000 ...

Страница 16: ...15 FIGURE 7 FLOW DIAGRAM AD 1200 to 2000 ...

Страница 17: ...FIGURE 8 FLOW DIAGRAM AD 2500 to 4000 16 ...

Страница 22: ...21 ...

Страница 23: ...22 ...

Страница 24: ...Pneumatech 4909 70th Avenue Kenosha WI 53144 Phone 262 658 4300 Fax 262 658 1945 www pneumatech com ...