19

Table 1 — Troubleshooting Guide, continued

Symptoms Cause Remedy

D. Compressor starts and runs –

short cycles on overload.

1. Low voltage, or phase unbalance.

2. Additional current going through

overload.

3. Overload protectors defective.

4. Run

capacitor

weak.

5. High discharge pressure.

6. Short in winding.

7. Current relay sticking.

1. Check voltage to be within ±10%

of voltage listed on name plate.

2. Check wiring diagram, check for

added electrical devices

connected thru protector.

3. Check current, replace.

4. Check capacitance, replace.

5. Refer to G 1-8.

6. Check resistance, replace

compressor.

7. Check floor level, tap & release.

E. Relay burned out.

1. Low or high line voltage.

2. Incorrect running capacitor.

3. Short

cycling.

4. Wrong

relay.

5. Incorrect

mounting.

1. Check voltage to be within ±10%

of voltage listed on name plate.

2. Replace with proper capacitance.

3. Refer to B and C.

4. Replace with proper relay.

5. Mount in correct, rigid position.

F. Capacitors burn out.

1. Improper

capacitor.

2. High line voltage.

1. Replace with proper capacitor.

2. Lower voltage to not more than

10% above rating.

G. Head pressure too high.

1. Refrigerant

overcharge.

2. Air in system.

3. Dirty

condenser.

4. Location

too

hot.

5. Defective condenser pressure

switch.

6. Defective fan motor.

7. Fan operating in wrong direction.

8. Defective water regulating valve.

1. Purge or vacuum and recharge.

2. Check for reason, repair.

3. Blow clean with compressed air.

4. Cool ambient, relocate unit, add

ventilation.

5. Repair or replace.

6. Replace.

7. Switch two wires at disconnect.

8. Adjust, repair or replace.

H. Head pressure too low.

1. Refrigerant

shortage.

2. Compressor suction or discharge

valves

inefficient.

3. Defective condenser pressure

switch.

4. Defective water regulating valve.

1. Repair leak and recharge.

2. Repair or replace.

3. Repair or replace.

4. Adjust, repair or replace.

I. Noisy

unit.

1. Mountings

loose.

2. Bent fan blade.

3. Fan motor bearing worn.

4. Refrigerant flooding back.

5. Compressor oil charge low.

1. Tighten mounting, etc.

2. Straighten or replace blade.

3. Replace.

4. Check expansion valve, adjust,

repair or replace. Check

crankcase heater.

5. Check oil level.

J. Frosted liquid line.

1. High side service valve partially

closed or restricted.

2. Restricted

filter/dryer.

1. Open valve or remove restriction.

2. Replace.

K. Frosted suction line.

1. Expansion valve and/or hot gas

bypass out of adjustment.

1. Adjust the hot gas bypass valve to

bring the suction pressure into the

proper range.

L. Top condenser coils cool when

unit in operation.

1. Refrigerant

shortage.

2. Compressor

inefficient.

1. Repair leak and recharge.

2. Repair or replace.

Содержание AD Series

Страница 1: ...Noncycling Refrigerated Air Dryers AD 750 to 4000 Series Owner s Manual 9829 2103 73 August 2009 ...

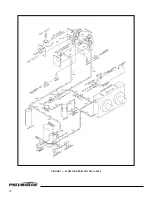

Страница 5: ...INSTALLATION INSTRUCTIONS 4 FIGURE 1 COMPRESSED AIR SYSTEMS RECOMMENDED INSTALLATION FLOW DIAGRAM ...

Страница 15: ...14 FIGURE 6 FLOW DIAGRAM AD 750 to 1000 ...

Страница 16: ...15 FIGURE 7 FLOW DIAGRAM AD 1200 to 2000 ...

Страница 17: ...FIGURE 8 FLOW DIAGRAM AD 2500 to 4000 16 ...

Страница 22: ...21 ...

Страница 23: ...22 ...

Страница 24: ...Pneumatech 4909 70th Avenue Kenosha WI 53144 Phone 262 658 4300 Fax 262 658 1945 www pneumatech com ...