129

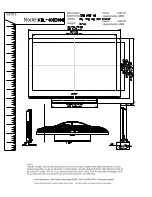

KRP-500P

5

6

7

8

5

6

7

8

A

B

C

D

E

F

Preparation before adjustment

[Replacement with the panel for service is completed.]

[To the Main flowchart (1)]

Turn the unit on. / [PO

N

]

Enter Factory mode. / [FAY]

Set PM/B1-B5 to CLEAR (to clear the pulse meter). / [CPM]

Set HR-MTR to CLEAR (to clear the hour meter). / [CHM]

Turn the unit off. / [POF]

Turn the unit on. / [PO

N

]

Enter Factory mode. / [FAY]

Display CMB MASK 01 (moving ramp). / [MKC S01]

Select

V

ideo 60-Hz sequence. / [

V

FQ S03]

∗

To reflect the results of log clearing for each correction function,

the unit must be turned off then back on again. Before adjust-

ment, be sure to turn the unit off then back on again.

Note:

*

W

hen you perform the adjustment with RS232C commands, issue the following commands in addition.

* If the unit is shut down in the middle of performing the adjustment flowchart, reissuing of the command is required.

[PAV S00]

: To set panel drive mode to Factory

[VFQ S03]

: To set Drive Sequence to

V

ideo 60-Hz

[SQM S01]

: To set Drive Sequence to

V

ideo

[WBI S01]

: To temporarily reset the Panel

W

B adjustment value to default (

W

BI S00 cancels this setting.)

[PGR S00]

: To set the gamma R value to that for Factory mode

[PGG S00]

: To set the gamma G value to that for Factory mode

[PGB S00]

: To set the gamma B value to that for Factory mode

[DIZ S03]

: Dither O

N

, L dither O

N

, noise OFF.

[$1

8

00000001]

: LUT mode O

N

Procedures for resetting

corrections for change

over time

Perform aging for 30 minutes.

Enter the tentative setting value of the replacement panel

Procedures for stabilizing the

panel before adjustment

Note:

The symbol "

α

" denotes the adjustment value plus 0.

Note:

"+0" shows

α

.

AWU1359 Data

VOF=113

VRP=01

8

V1F=13

8

V3F=12

8

+

α

Indication example of the adjustment label

of service panel

Data 08/02/28 Chassis CXX99999

Time 18:27 Pnl FD4A0808100123

V4F=149 Hour Meter

_ _ _ _ _ _ _ _ _ _

H

Setting Item

Tentative Setting Value

V

OL SUS / [

V

SU

∗∗∗

] 128

V

OL OFFSET / [

V

OF

∗∗∗

]

V

OF indication value

V

OL RST P / [

V

RP

∗∗∗

]

V

RP indication value

V

OL XPOFS1 / [

V

X1

∗∗∗

] 085

V

OL XPOFS2 / [

V

X2

∗∗∗

] 063

V

OL Y

N

OFS1 D / [

V

1F

∗∗∗

]

V

1F indication value

V

OL Y

N

OFS3 D / [

V

3F

∗∗∗

]

V

3F indication value +0

V

OL Y

N

OFS4 D / [

V

4F

∗∗∗

]

V

4F indication value

V

OL Y

N

OFSA D / [

V

YF

∗∗∗

] 128

∗

To store the

V

FQ S03 command in memory, transmit it after

displaying the mask.

∗

Each setting value described on the adjustment label

denotes an indicated data value but not a real voltage value.

Therefore, just enter the data value as a setting value.

Содержание KURO KRP-500P

Страница 11: ...11 KRP 500P 5 6 7 8 5 6 7 8 A B C D E F 2 3 PANEL FACILITIES WYSIXK5 and WYS5 types only LFT and WA5 types ...

Страница 12: ...12 KRP 500P 1 2 3 4 A B C D E F 1 2 3 4 Remote Control Unit for WYSIXK5 and WYS5 types ...

Страница 13: ...13 KRP 500P 5 6 7 8 5 6 7 8 A B C D E F Remote Control Unit for LFT type ...

Страница 14: ...14 KRP 500P 1 2 3 4 A B C D E F 1 2 3 4 Remote Control Unit for WA5 type ...

Страница 19: ...19 KRP 500P 5 6 7 8 5 6 7 8 A B C D E F ...

Страница 20: ...20 KRP 500P 1 2 3 4 A B C D E F 1 2 3 4 4 BLOCK DIAGRAM 4 1 OVERALL WIRING DIAGRAM 1 2 ...

Страница 22: ...22 KRP 500P 1 2 3 4 A B C D E F 1 2 3 4 4 2 OVERALL WIRING DIAGRAM 2 2 ...

Страница 23: ...23 KRP 500P 5 6 7 8 5 6 7 8 A B C D E F OVERALL DIAGRAM KRP 500P ...

Страница 139: ...139 KRP 500P 5 6 7 8 5 6 7 8 A B C D E F ...

Страница 148: ...148 KRP 500P 1 2 3 4 A B C D E F 1 2 3 4 9 5 REAR SECTION POWER SUPPLY P8 Refer to 9 6 FRONT SECTION ...

Страница 156: ...156 KRP 500P 1 2 3 4 A B C D E F 1 2 3 4 9 9 PANEL CHASSIS SECTION ...