Theory of Operation

1 Introduction

13

Gases with paramagnetic properties are attracted by magnetic fields. In a magnetic field the density and

thus the heat conductivity of such gases is increased. The gas analyzer determines the amount of oxygen

in the gas sample by measuring its heat conducting properties while switching a magnetic field on and

off inside the O

2

sensor. This way the changes in the oxygen present in the magnetic field can be

measured, and the amount of oxygen in the gas sample can be calculated.

Pump

The software-controlled pump generates the flow through the system and pulls the gas from the airway

adapter through the measurement subsystems to the exhaust outlet. It also delivers the zero calibration

gas to the sample cells of the measurement subsystems for the periodic zero procedures and it exhausts

the patient’s sample gas, the zero calibration and field calibration gases.

The flow-rate control logic drives the pump as hard as necessary to maintain the selected flow rate. A

partial occlusion or an inefficient pump results in the pump being driven harder. A serious occlusion

results in the pump being driven at or near its maximum load. If, as a result of this occlusion, the

desired flow rate cannot be upheld, an occlusion INOP is triggered.

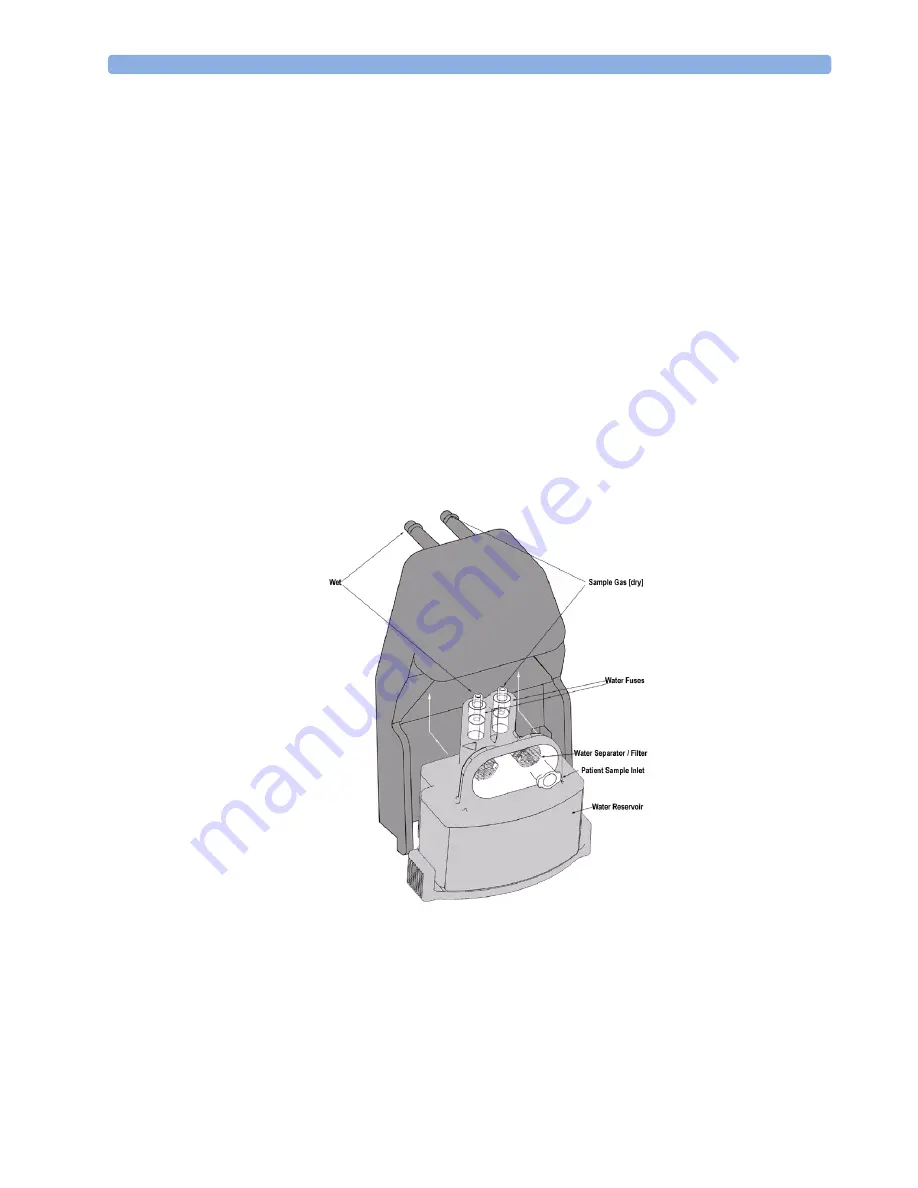

Watertrap

Figure 1 Watertrap

The watertrap consists of two water separation filters, two water fuses and a water reservoir. The gas

sample coming from the patient may contain fluids which are separated from the gas at the first water

separation filter. The gas is then split into two paths, the “measurement” path with the main part of the

total gas flow (including water vapor) continuing on the “dry” side of the separation filter and the

“drainage” path (containing any liquid droplets) with the smaller amount of the total flow continuing

on the “wet” side of this filter through the water reservoir. At the pump both gas paths are recombined.