HD5720/30

16-23

OTHER FAILURES

Problem description

Actions to perform

Hints/tips/solution

1.

During heating up water is

dripping from the Brewing unit.

OR

I selected hot water but the

water is leaking via the brewing

unit inside of the appliance.

• The valve construction in the (yellow

tube) thermo heater became defect.

• Check the O-rings in the brewing

unit (pos 41)

• Check the spring in the brewing unit

(pos 44)

• Check the shaft in the brewing unit.

(pos 42)

2.

Coffee is not coming out of the

spout.

• Check if the holes of the spout are not

clogged.

• Check if the mobile drawer inside the

service door is blocked and cannot swing.

• The coffee is not running out of the

brewing unit spout but is leaking through

the brewing unit.

• Clean or open the holes with a

needle.

• Check the function of the drawer and

clean it thoroughly so it can swing

again.

• Check the O-rings in the brewing

unit otherwise replace brewing unit.

3.

The coffee is not hot.

• Mostly the problem is caused by the fact

people use big not pre-heated mugs for

small amounts of Coffee.

• Increase the coffee temperature in the

menu.

• Measure the Coffee temperature see

instruction “Temperature measurement”.

• If the temperature is really too low,

descale appliance.

• Check function of NTC

• Replace coffee heater.

4.

The coffee is not creamy

enough.

• The coffee is ground too coarsely.

Turn the grinding coarseness knob one

setting anticlockwise while the mill is

grinding coffee beans.

• Check fi nes of the grinder; adjust

grinder see instruction Grinder

adjustments.

5.

The coffee is too strong.

• The coffee is ground too fi nely.

Turn the grinding coarseness knob

one setting clockwise while the mill is

grinding coffee beans.

• Change the coffee strength with the

coffee strength button

• Check fi nes of the grinder; adjust

grinder see instruction Grinder

adjustments.

6.

The coffee is too weak.

• The coffee is ground too coarsely.

Turn the grinding coarseness knob one

setting anticlockwise while the mill is

grinding the coffee beans.

• Change the coffee strength with the

coffee strength button.

• Check fi nes of the grinder; adjust

grinder see instruction Grinder

adjustments.

7.

The coffee tastes bad.

• Clean the appliance with the ‘cleaning’

function in the menu.

• Descale the appliance with the ‘descaling’

function in the menu.

• Taste is really user depended, only

cleaning, descaling and checking

of the grinder adjustment are

possibilities to check. (assumption is

that the appliance functions normal!)

8.

The water system has been

damaged due to the fact the

appliance has been stored /

transported in freeze cold.

If the water system has been frozen, most

probably the appliance is not able to make

Coffee any more.

The water cannot reach the Coffee powder

any more or water is leaking out of the

brewing unit.

The valve used in the brewing unit (yellow

tube) is mostly the part that has to be

replaced.

• Check the O-rings in the brewing

unit (pos 41)

• Check the spring in the brewing unit

(pos 44)

• Check the shaft in the brewing unit.

(pos 42)

• Check the valve (pos 43)

• Follow procedure “Empty water

system” when the appliance will be

transported in Winter time.

TROUBLE SHOOTING

= changed

Содержание HD5720/30

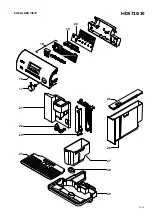

Страница 20: ...HD5720 30 20 23 EXPLODEDVIEW 9 10 11 12 13 15 14 1 2 4 3 5 7 8 6 ...

Страница 21: ...HD5720 30 21 23 EXPLODEDVIEW 17 16 24 25 19 20 28 29 22 21 23 27 26 18 ...

Страница 22: ...HD5720 30 22 23 EXPLODEDVIEW 47 48 49 50 31 45 34 35 36 38 39 37 32 30 31 A A 46 51 42 41 41 43 44 41 40 33 ...