HD5720/30

12-23

TROUBLE SHOOTING

Technical related problems.

Warning:

Live Voltage is applied to the micro switches used in the appliance!!!!!

Always disconnect plug from the mains when repairing!

When the appliance generates a GENERIC ALARM message, the only way to reset this is

by unplugging the power plug from the mains.

FAILURES AT PLUGGING IN APPLIANCE

Problem description /

“Error” message displayed

Actions to perform

Hints/tips/solution

1.

Appliances doesn’t work

at all.

Check if main voltage is applied on the main

PCB (vertical PCB on the right side) by

measuring the voltage (220 - 230 V) on the

connector F3 and F4.

(see electrical drawing scheme)

If no voltage is present:

check power cord and connections!

If voltage is present, check all electrical

connections on the PCB, otherwise exchange

PCB.

2.

MESSAGE

GENERIC ALARM !

• Check micro switch

(M1)

top position

brewing unit and it’s circuit.

• Check NTC sensor

(J5)

heater and it’s

circuit.

• Check Hall sensor

(J3B)

motor lift and it’s

circuit.

• Micro switch is NC (normally closed)

(exchange switch)

• Value NTC resistor at 23 °C

±

110 k

Ω

➟

±

95 °C = 5.3 k

Ω

• Value measured on PCB

J5

(without NTC)

±

10 k

Ω

• If the GENERIC ALARM message

appears after the brewing unit went down,

most probably the Hall sensor/connections

is the problem.

(counting of pulses starts after actuating

the

brewing unit_down_position M2

, so

going up direction!)

3.

MESSAGE

PLEASE WAIT......

• If a normal motor sound of the brewing

unit lift is noticed, but the brewing unit

doesn’t move, check the driving belt.

• If a motor sound is noticed and afterwards

you hear a hard noise sounding like a

blocked motor and the brewing unit stays

at bottom position, check the micro switch

(M2)

bottom position brewing unit and it’s

circuit.

• If no motor sound is noticed, check the

wire connection of the motor and see if

voltage has been applied on the motor side.

• If no motor sound is noticed and also no

voltage has been measured on pins

F7 &

F8 PCB

probably the 2 relays on the main

PCB became defect.

• Belt broken, replace belt.

• Replace micro switch (

M2)

.

• If voltage on the motor circuit board has

been applied, motor is probably defect.

Exchange total brewing unit lift assy.

• Exchange main PCB

4.

MESSAGE

CLOSE DOOR !

• Close the service door.

• Check the function and circuit of micro

switch

(M4)

.

• Check if the micro switch mechanical will

be activated if the door is closed.

• Exchange micro switch.

(M4)

.

5.

MESSAGE

INSERT WASTE BIN !

• Place waste bin.

• Check the function and circuit of micro

switch

(M3)

.

• Check if the micro switch mechanical will

be activated if the waste bin is placed.

• Exchange micro switch.

(M3)

.

!

= changed

Содержание HD5720/30

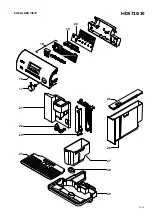

Страница 20: ...HD5720 30 20 23 EXPLODEDVIEW 9 10 11 12 13 15 14 1 2 4 3 5 7 8 6 ...

Страница 21: ...HD5720 30 21 23 EXPLODEDVIEW 17 16 24 25 19 20 28 29 22 21 23 27 26 18 ...

Страница 22: ...HD5720 30 22 23 EXPLODEDVIEW 47 48 49 50 31 45 34 35 36 38 39 37 32 30 31 A A 46 51 42 41 41 43 44 41 40 33 ...