10

General

Store and transport components of the

Hydraulic Head Spindle Device VST so it

is not possible that they can change their

position unintentionally or are damaged.

Do not drop the Hydraulic Head Spindle

Device VST.

During the moving procedure, ensure

that components are picked up and set

down so that unintentional falling over,

falling apart, sliding, falling down or

rolling is avoided.

Do not place any loads on the Hydraulic

Head Spindle Device VST.

Use original PERI storage and transport

systems, e.g. crate pallets.

The components are to be stored in a

dry and clean condition as well as pro-

tected against corrosion at temperatures

from – 20 °C to + 40 °C.

The Hydraulic Head Spindle Device VST

must be protected against the effects of

the weather and aggressive materials if

safety is then likely to be affected!

During transport, intermediate storage or

when remaining suspended on the load,

ensure that the product remains free of dirt

and that its functionality is not affected.

Storage and transportation

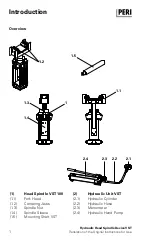

Hydraulic Unit VST

Never lift the Hydraulic Device VST using

the hose or swivel couplers. Only trans-

port by holding the pump and cylinder.

The vent and filler cap (2.4a) must be

closed before transporting the pump in

order to prevent any loss of oil.

If the hydraulic components are separat-

ed, the dust caps must be screwed on

immediately so that no impurities can

cause a subsequent malfunction of the

hydraulic system.

When transporting or placing in tempo-

rary storage, the hydraulic components –

hose, cylinder and hand pump – must be

separately stored and transported in the

designated aluminum case. (Fig. 1)

Introduction

Hydraulic Head Spindle Device VST

Translation of the Original Instructions for Use

EN_BA_Hydr_Kopfspindeleinheit_VST.indb 10

01.04.16 11:25

Содержание 117465

Страница 27: ...25 Hydraulic Head Spindle Device VST Translation of the Original Instructions for Use...

Страница 44: ...42...

Страница 45: ...43...