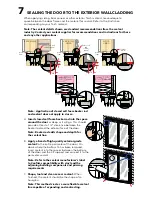

A.

Place three 3/8" beads of sealant.

The first bead should

be approximately 3/4" from the exterior of the rough

opening, the second 2-1/2" in from the first bead of sealant.

OX/XO doors only:

Place a third bead of sealant in the

groove of the sill support or 1/4" from the exterior edge of

the wood blocking.

"

TWO OR MORE PEOPLE WILL BE REQUIRED FOR THE

FOLLOWING STEPS.

&YUFSJPS

#

B.

Insert the door from the exterior of the building.

DO NOT slide the bottom of the door into the

opening.

Sliding will damage the sealant lines. Place

the bottom of the door at the bottom of the

opening, then tilt the top into position.

Center the door between the sides of

the opening to allow equal clearance for

shimming, and insert one roofing nail

in the first hole from the corner on each

end of the top nailing fin (see inset).

These are used to hold the door in place

while shimming it plumb and square.

#

C.

Plumb and square door.

Insert shims, as necessary,

between the door and the sides of the rough

opening starting up 6" from the bottom of the door.

Keep shims back 1/2" from interior face of window.

Note: DO NOT shim above the door. DO NOT

OVER SHIM.

Interior

3C

'JYFE1BOFM

1SFESJMMFEQBOFMSFUBJOFSIPMFT

5ISFTIPME

&

D.

Fasten the door to the opening

by driving 2" galvanized roofing

nails into each pre-punched hole

in the nailing fin.

E.

Install roller retainers.

Position and secure the two roller retainers provided by drilling

pilot holes through the pre-drilled holes into the sill support. Apply sealant to the holes

and insert screws as specified below:

Aluminum sill support:

9/64" pilot holes, # 8 x 3/4" thread-cutting screws (provided).

Wood blocking:

1/8" pilot holes, #8 x 2-1/2" flat-head wood screws (provided).

3

SETTING AND FASTENING THE DOOR

3A

3B

3B

3C

%

3D

3E

Содержание 803V0102

Страница 12: ...This page left blank intentionally ...