Mount the balance shaft on the drive shaft with

M10 x 150 bolt. Use a striking nutrunner (and a

long H8 hex bit socket). If the balance axis is loose,

there will be different measurement results.

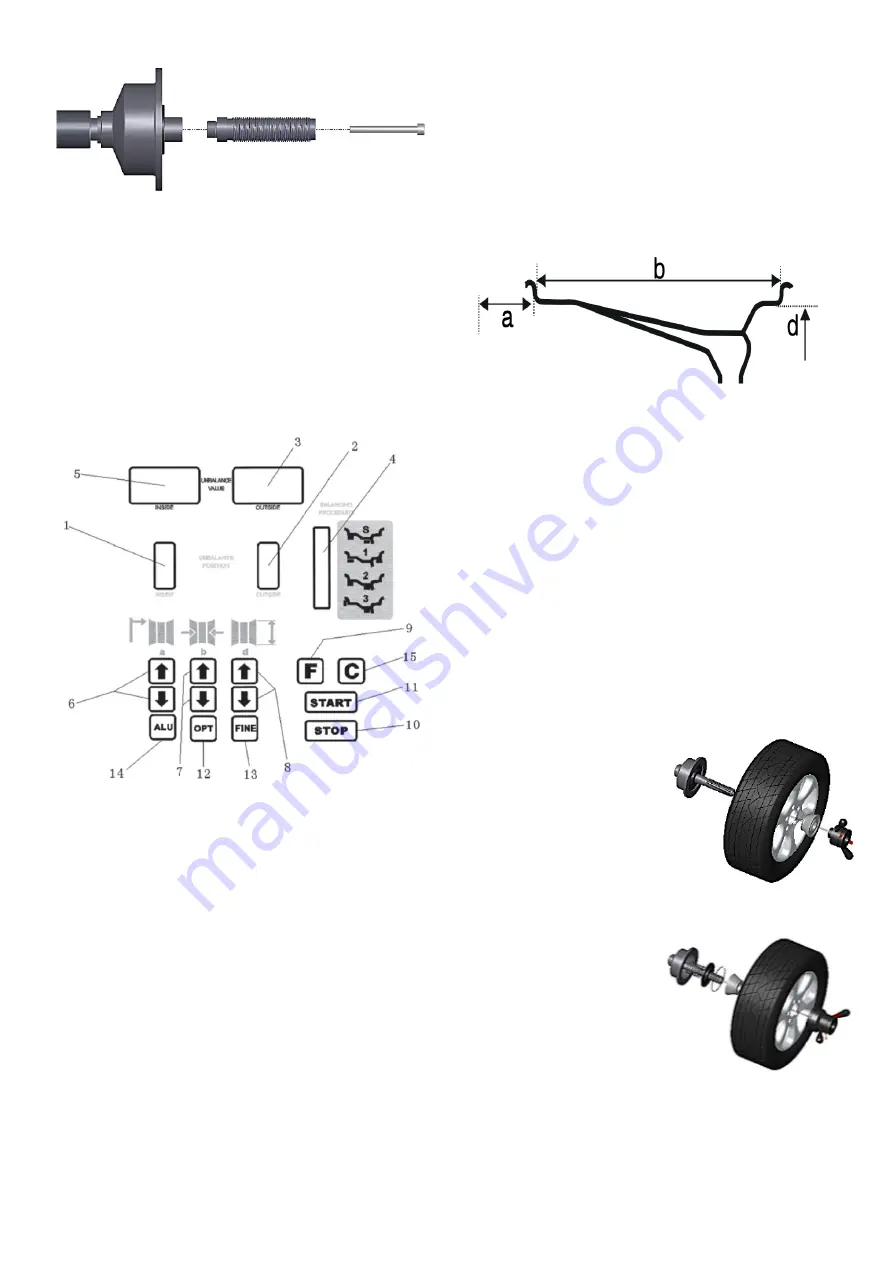

The display is integrated with the machine.

NOTE! Use only your fingers to press the buttons.

Never use the counterweight pliers or other poin

-

ted objects.

Display and control panel

1. Indicator of the inside balance weight position.

2. Indicator for the outside balance weight

postion.

3. The display shows the outside correction

weight.

4. Indicator for the adhesive weight position in the

”ALU” position.

5. The display shows the inside correction weight.

6. Manual adjustment of the rim measured

distance (a).

7. Manual adjustment of the rim width (b).

8. Manual adjustment of the diameter (d) on the

rim.

9. Selection of static or dynamic correction.

10. Stop button.

11. Start button.

12. Optimization of imbalance.

13. Shows exact unbalanced weight.

14. Program selection for aluminum rims.

15. Recalculation of the balance sheet weight.

Combination functions for buttons

F + C .................................................. Self-calibration

F + FINE .............................................. Self-diagnosis

F + STOP .................... Adjusting the protectivehood

F + (a-) + (a +) .............Dimensions in inches or mm

STOP + C ........................... Reset to factory settings

Rim parameters

Assembly and disassembly of wheels

Before mounting the centering cone on the balance

shaft of the machine, check that the surfaces are

on the centering cone and balance shaft are clean,

no sand or dirt, and the tire is also clean. Remove

any previous balance weights, check air pressure

and that the rim is not damaged.

Then fit the appropriate centering cone.

Mount the wheel on the balance shaft and fasten

with the quick nut.

Remember that poor centering leads to

unnecessary imbalance.

Position of centering cone in most cases of

aluminum rims. (To protect the rim on the outside

against the quick nut).

Positive positioning is com

-

monly used. It works easily

and is useful for

different types of sheet me

-

tal rims and thin

aluminum rims. Placement

of centering cone in most

cases of sheet metal rims.

Negative positioning is

used to protect the inner

hole of the rim and the

main axle is positioned

exactly even if the outside

of the wheel is deformed.

Used for all sheet metal

rims, especially thick sheet

metal rims. rims, especially

thick sheet metal rims.

Disassembly of wheels

Release the quick nut by turning it

counterclockwise and then release it with the red

levers. Remove the cone and lift the wheel, being

careful not to scratch the balance shaft..

Содержание 506799

Страница 1: ...Automatic wheel balancer U 800 D ckbalanseringsmaskin U 800 Item No 506799...

Страница 12: ...Reservdelslista...

Страница 13: ......

Страница 14: ......

Страница 16: ...Funktionsdiagram...

Страница 17: ...Blockschema...

Страница 18: ......

Страница 29: ...Spare parts list...

Страница 30: ......

Страница 31: ......

Страница 33: ...Function diagram...

Страница 34: ......

Страница 35: ......

Страница 36: ...Verktygsboden Erfilux AB K llb cksrydsgatan 1 SE 507 42 Bor s Verktygsboden Bor s Sweden 0120504 03...