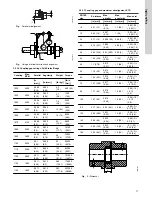

3.3.2.1 Foundation, grout and anchor bolt installation

1

2

3

4

5

6

7

8

11

9

10

TM054775

Fig.

Foundation, grout, and anchor bolt installation

Position

Description

1

Finished grouting

2

0.75-1.25 in (19-32 mm) allowance for grout

3

Formwork

4

Pipe sleeve

5

Washer

6

Base plate

7

0.2-0.4 in (5-10 mm)

8

Lug

9

Grout

10

Wedges or shims left in place

11

Top of foundation

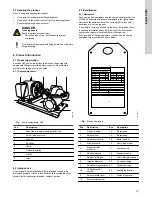

3.3.3 Positioning the pump

When the raised concrete foundation has been poured and allowed

to set, proceed as follows:

WARNING

Overhead load

Death or serious personal injury

‐

Never attempt to lift the entire pump by means of

eyebolts screwed into the driver mounting holes. This

attachment point may not be strong enough to carry

the weight of the entire unit.

Adequate space above the installation site must be

provided to accommodate rigging and the longest section

of the pump to be handled.

1.

Lower the base plate over the anchor bolts and rest it on loose

adjustment wedges or shims placed near each anchor bolt and

at intervals not exceeding 24 in (610 mm) along each side.

2.

Place the shims or wedges so that they raise the bottom of the

base plate 0.75-1.25 in (19-32 mm) above the foundation,

allowing clearance for grout.

3.

Level the pump shaft, flanges, and base plate using a level,

adjusting the wedges or shims, as required.

If the pump is equipped with jacking screws, use

them to lift the pump and adjust the wedges or shims.

4.

Make sure that the pipes can be aligned to the pump flanges

without placing any strain on either flange.

5.

After pump alignment has been established, put nuts on the

anchor bolts and tighten them just enough to keep the base

plate from moving.

6.

Construct a formwork around the concrete foundation and pour

grout inside the base plate. The grout will compensate for the

uneven foundation, distribute the weight of the pump, and

prevent shifting.

Use an approved, non-shrinking grout.

7.

Allow for the grout to cure fully before proceeding with torquing

the anchor bolts and the pipe connections.

8.

After the grout has thoroughly hardened, check the anchor

bolts and tighten them if necessary. Recheck the pump

alignment after tightening the anchor bolts.

TM072276

Fig.

Raising the base plate with wedges or shims

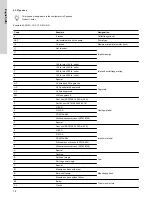

3.3.4 Dowel pins

To comply with the Hydraulic Institute recommendations, all pumps

should be dowelled.

The pump feet can be drilled for dowels at the factory or in the field.

Doweling the pump feet accomplishes the following:

•

Prevents lateral movement.

•

Eases realignment if the pump is removed from the base.

•

Temporarily holds the pump if the hold-down bolts loosen.

3.3.5 Installing dowel pins

If dowel holes were not drilled in the pump feet at the factory then

determine the dowel and hole size by measuring the diameter of the

mounting hole in the pump foot and subtract 3/8".

Peerless recommends the use of straight dowel pins as described

in the following steps:

1.

Check the coupling alignment and correct if necessary.

2.

Drill holes in opposite pump feet. The holes should be 1/64"

smaller than the dowel diameter.

3.

Clear the debris.

4.

Ream the holes in the pump feet and base to the correct

diameter. Allowing for a push fit.

5.

Clear the debris.

6.

Insert the dowels to a depth that leaves sufficient thread to

attach a nut.

7.

Thread the nuts onto the dowel and tighten.

8

English (US)